Rev. 20.03.2017

Rev. 20.03.2017

Functioning

Control system: the PID module

The PID module has two functions: to measure and to control the heating. The temperature measurement

in the heating coil is made at regular intervals. This information is transmitted to the PID module as current

value, and gets compared to the value set by the user.

- If the current value is inferior to the set value, the PID module makes the

device heat

- If the current value is superior or equal to the set value, the PID module

stops the heating.

This cycle gets repeated at a 2-second-intervall. Therefore, a high grade of

precision is ensured.

Contrary to a thermostat the PID module’s benefits lie in the combination of flexibility, efficiency and

precision.

The basic thought is comparable to a car: there is a gas pedal for accelerating (rapid heating), a break to

regulate the gained momentum (prevents overheating) and a steering wheel to coordinate exact realization

of the goal (temperature regulation precise to the degree).

Thus, the energy consumption can be optimized, and the material fatigue

can be compensated: Therefore system combines several advantages in

comparison to a thermostat.

How does the metal get molten?

The PID module controls the power flow to the heating coil (ON/OFF system). When the circuit is closed,

the heating coil gets warm and transfers the heat to the crucible which forwards the warmth to the metal

(passive heating without direct contact). The metal gets hot and liquid when it reaches its smelting point.

EN

12

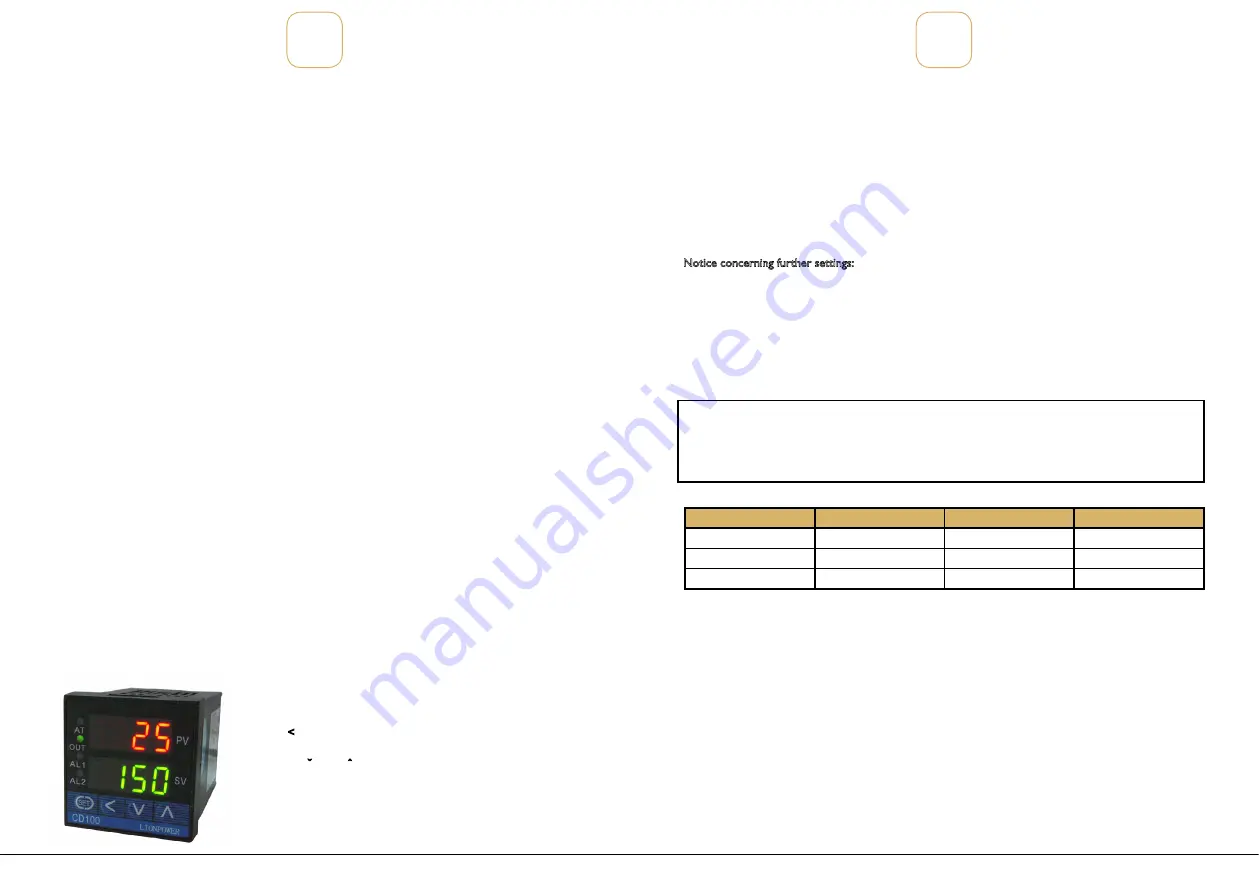

OPERATION

1.

Put the chosen metal in the crucible (see instructions for metals melting )

2.

Plug the device in the power source

3.

Press the ON/OFF button

4.

Set the temperature (smelting temperature)

- Press the SET button: SV (= set value)

flashes. Every single digit can be set: to

select the digit you want to change, press

the „

<

“ button. To change its value, use the

buttons “

ˇ

” and “

ˆ

“.

- To save the selected value, press SET again.

- Notice: If you don´t save the selected value,

the device will automatically go back to the

main display mode without holding the

value which was set.

5. The device is starting the heating process. The „OUT“- light is lit until the temperature reaches the

chosen value.

6. As soon as the temperature is reached, the device stops heating. The “OUT” light flashes and the

temperature remains constant.

7. If you don´t want to use the whole quantity of molten metal, take the crucible out of the heating

chamber with the tong provided with the furnace, while the power is turned on

8. Cast the metal into the mold and put the crucible back into the heating chamber.

9. Turn the furnace out as soon as the whole quantity of molten metal was used.

10. For melting smaller amounts there are no disadvantages.

Notice concerning further settings:

Generally speaking, the PID modules enables several complex settings, these are not only very diverse but

also complicated. The fine tuning of the factors regulating the temperature is easily modified, which can lead

to a dysfunction of the device, so that this possibility was locked by the manufacturer. The lights “AL” and

“AT” are also deactivated. In case of any problem with the device, please contact the seller to guarantee a

secure use of the device.

EN

13

The lamps “AL“ and “AT“ are usually inactive. If one of the two LEDs is light up this is an indication for a

functional error. Please approach your retailer in such a case to ensure safe use of the device.

INSTRUCTIONS FOR METALS MELTING

IMPORTANT:

The graphite crucible is only adapted to melt noble metals!

Aluminum, lead, brass, bronze… can only be molten in a crucible which is designed for those kind of metal!

(Our crucibles are designed for melting gold, silver and copper only).

List of the metal types which can be molten in the crucible provided with the device:

Please consider that the crucible shouldn´t be completely filled to reach an optimal result. If you overfill the

crucible, the device won´t be able to produce the heat needed to let the metal melt. Moreover, the melting

process often produces vapors. If you overfill the crucible, it can lead to overpressure and the use of the

device gets dangerous for the user, at the latest by opening the cover.

Please buy an adapted crucible to melt other metals. Always inform yourself about the production of vapors

during the melting process to check the compatibility of the device with your intentions.

Metal

Symbol

Density

Fusion point

Copper

Cu

8.92 g/cm³

1084.62°C

Silver

Ag

10.49 g/cm³

961.78°C

Gold

Au

19.30 g/cm³

1064.18°C

HOW TO EXCHANGE THE HEATING COIL

CAUTION:

Never open the device without authorization of your seller. This can lead to a loss of

guarantee!

The heating coil is made out of ceramic, so it is constructed for a long time of use - though, it may

happen that the heating coil gets damaged, and you have to exchange it. To do it, please follow these given

instructions