14

Power Source

Connecting to a power source:

1. Ensure that the battery to connect to is

12V DC and that it is charged when in use.

2. Connect the red connector to the positive

(+) terminal and the black connector to the

negative (-)terminal.

The wiring loom uses a 15A blade fuse.

Filling

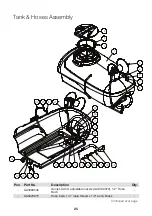

When filling the sprayer it is necessary to

use an external water source and wear the

appropriate PPE.

The following steps should be followed when

filling the tank:

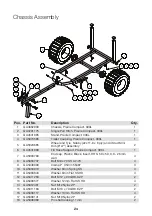

1. Connect the sprayer to tow vehicle and

park on level ground.

2.

The pump should be turned off.

3. Remove the tank lid.

4. Add 20% of the tanks volume of clean

water, or more, if the chemical is in a

denser form e.g. powder.

5. Add chemical as required. Some agitation

will take place as the rest of the water is

added.

6.

Use external water source to fill main tank

(Do not exceed the tank capacity).

7. Replace the tank lid and ensure that it is

secure prior to switching on pump. You are

now ready to use the sprayer.

Spray Application

NOTE

: It is the responsibility of the operator

to ensure that the chemical mix is sufficiently

agitated and that the conditions are right

to start spraying. Operators must wear the

appropriate PPE.

1.

If wanting to spot spray only, then turn off

the ball valve in the boom line.

2. Switch pump on.

3. Allow pump to build pressure.

4. It is recommended to set the regulator to

maximum pressure (45 PSI) when using

the spray gun only. Adjust the regulator if

necessary.

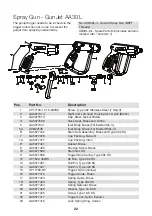

5. Engage the trigger on the spray gun to

commence spot spraying.

6.

If fitted,to spray from the boom only, make

sure the ball valve leading to it is open.

Adjust the nozzle pattern by rotating the

nozzle in the appropriate direction as

required.

7. Adjust the pressure regulator to raise or

lower the spray rate to suit application. This

will ensure even and consistent coverage of

the target.

NOTE

: Refer to your chemical manufacturer's

information for determining appropriate spray

rates or consult an agronomist for further help.

Agitation should take place when filling or

through another method as deemed suitable

by the operator.

Identification

When ordering parts or requesting service

information for your sprayer, it is important to

quote the serial number and the purchase date

of your machine. This will assist with receiving

the most accurate information. The location of

the stamped ID plate is shown below.