53

5

Accessories

049

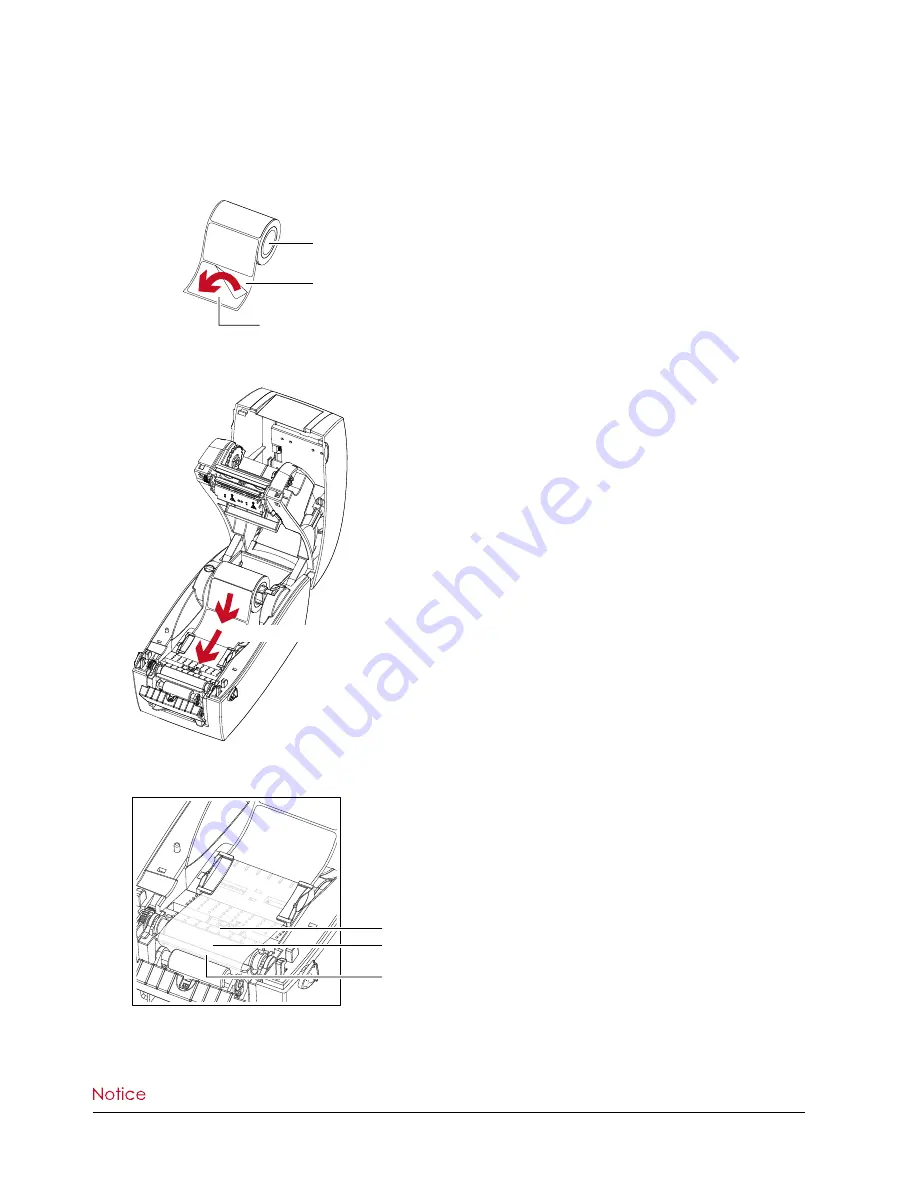

2. Feed the Label stock through the label guides.

3. Pull the label liner through the platen and the steel of the label dispenser.

*

***

Labels should be at least 25 mm high.

Through the label guides

LABEL LINER

PLATEN

STEEL

Loading Label Roll with the Label Dispenser Module

1. Remove the first label from the label stock.

Tear a label

THE FIRST LABEL

LABEL STOCK

LABEL LINER