Start-up 9

0020289288_02 MicraCom Installation and maintenance instructions

25

–

If the entire filling and supplementary water quantity dur-

ing the operating life of the system exceeds three times

the nominal volume of the heating installation, or

–

If the guideline values listed in the following table are not

met, or

–

If the pH value of the heating water is less than 8.2 or

more than 10.0.

Total

heating

output

Water hardness at specific system volume

1)

≤

20 l/kW

> 20 l/kW

≤

50 l/kW

> 50 l/kW

kW

ppm

CaCO

₃

mol/

m

³

ppm

CaCO

₃

mol/

m

³

ppm

CaCO

₃

mol/

m

³

< 50

< 300

< 3

200

2

2

0.02

> 50

to

≤

200

200

2

150

1.5

2

0.02

> 200

to

≤

600

150

1.5

2

0.02

2

0.02

> 600

2

0.02

2

0.02

2

0.02

1) Nominal capacity in litres/heating output; in the case of multi-

boiler systems, the smallest single heating output is to be used.

Caution.

Risk of material damage if the heating

water is treated with unsuitable additives.

Unsuitable additives may cause changes in

the components, noises in heating mode and

possibly subsequent damage.

▶

Do not use any unsuitable antifreeze and

corrosion inhibitors, biocides or sealants.

No incompatibility with our products has been detected to

date with proper use of the following additives.

▶

When using additives, follow the manufacturer's instruc-

tions without exception.

We accept no liability for the compatibility of any additive or

its effectiveness in the rest of the heating system.

Additives for cleaning measures (subsequent

flushing required)

–

Adey MC3+

–

Adey MC5

–

Fernox F3

–

Sentinel X 300

–

Sentinel X 400

Additives intended to remain permanently in the

installation

–

Adey MC1+

–

Fernox F1

–

Fernox F2

–

Sentinel X 100

–

Sentinel X 200

Additives for frost protection intended to remain

permanently in the installation

–

Adey MC ZERO

–

Fernox Antifreeze Alphi 11

–

Sentinel X 500

▶

If you have used the above-mentioned additives, inform

the end user about the measures that are required.

▶

Inform the end user about the measures required for frost

protection.

9.3

Filling the heating installation

Note

After each start-up, the product works at reduced

output when starting in order to facilitate the heat

transfer effect. This does not apply for check pro-

grammes and does not result in any loss of com-

fort for the end user. Status code

S.58

corres-

ponds to this phase. The display shows a tem-

perature of approx. 50 °C in this phase.

1.

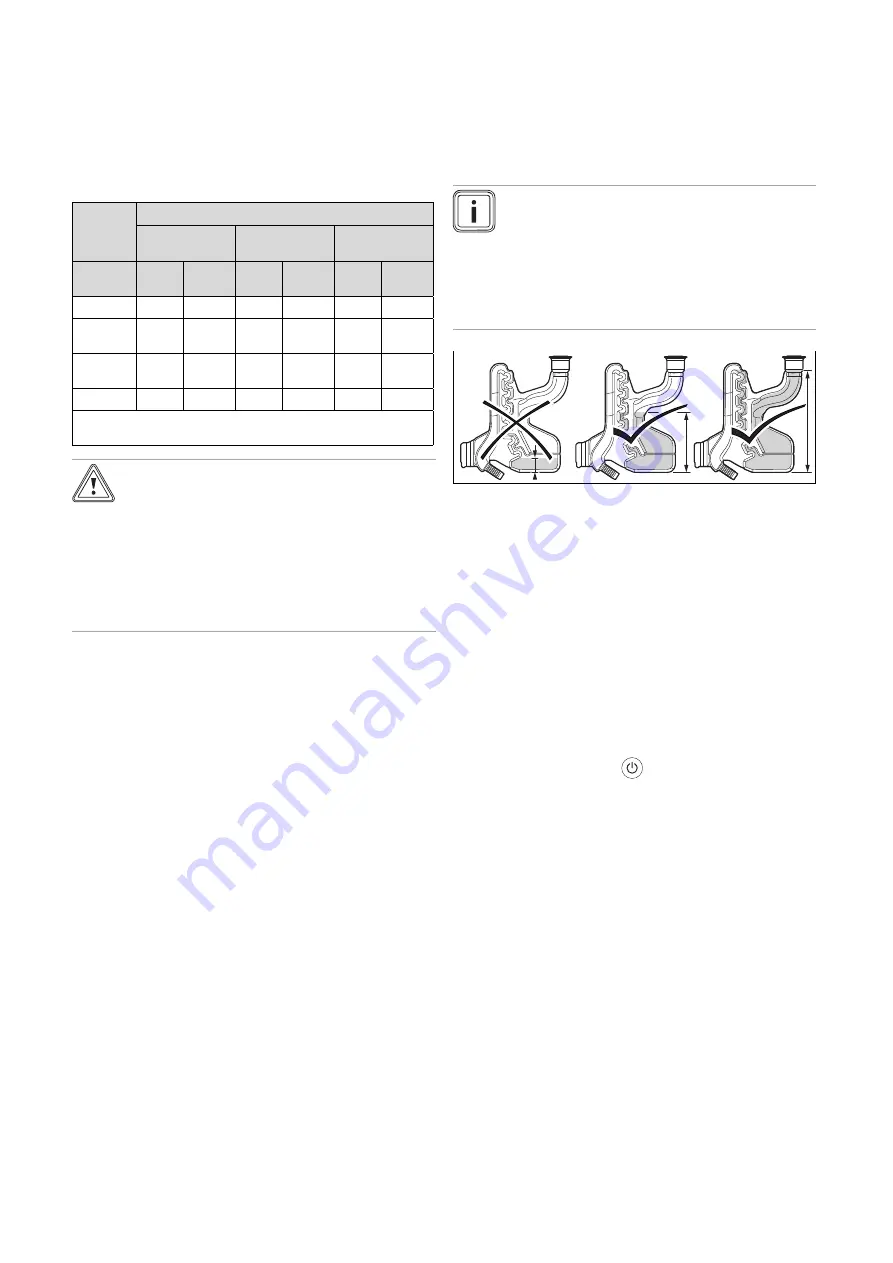

Ensure that the condensate siphon has been filled cor-

rectly.

2.

Before filling the heating installation, ensure that it has

been flushed out sufficiently.

3.

Connect the filling/draining cock in the heating install-

ation to a heating water supply in accordance with the

relevant standards.

4.

Open all of the thermostatic radiator valves and, if re-

quired, the service valves.

5.

Open the heating water supply and the filling tap so that

the heating water flows into the heating installation.

◁

The heating circuit is automatically purged via the

hose that is connected to the pump.

Starting up the product

6.

Press the on/off button

.

◁

The display shows the basic display.

7.

Start check programme

P.08

. (

Check programmes (

◁

The product's heating circuit is automatically purged

via the hose that is connected to the pump.

8.

Purge the highest radiator until water flows out of the

purging valve without bubbles.

9.

Purge all other radiators until the entire heating installa-

tion has been completely filled with heating water.

10. Close all purging valves.

11. Fill with heating water until the required filling pressure

is reached.

–

0.10 to 0.14 MPa (1.00 to 1.40 bar)

▽

If the heating installation extends over several

storeys, higher filling pressures may be required to

avoid air entering the heating installation.

12. Close the filling tap and the heating water supply.

13. Check all of the connections and the entire circuit for

leaks.