4. Set the Table to desired height then

tighten the table support clamp handle

to lock the table support in place.

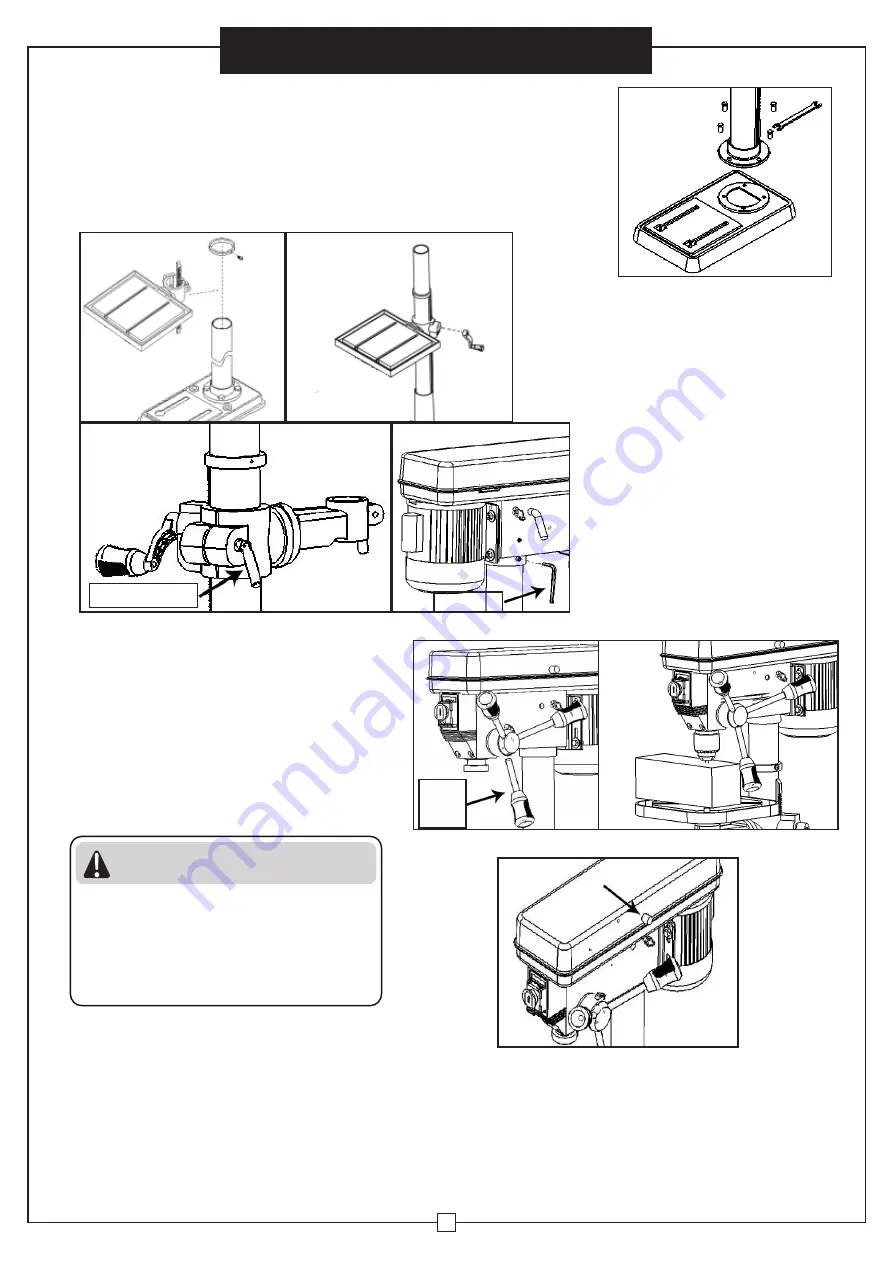

1. Place the Base Platorm (9) on the bench top and attach the Column

Assembly (13) using four hex bolts.

2. Place the rack into the Table (10) and attach to the Column Assembly. Install

the Column Collar (14) above the lifting rack using the set screw it came

with.

3. Attach Cranks (12) to table support and vise. Secure with set screws.

6. Attach the Feed Handles (9) to the feed

crank hub and secure the hub to the Head

Assembly (1).

7. Rotate the chuck sleeve clockwise open the

jaws of the chuck. Make sure the chuck jaws

are fully opened and receded into the chuck.

8. Push the chuck into the spindle. Using a

wooden or rubber mallet, tap the chuck up to

secure it onto the spindle shaft.

WARNING

Product is shipped with protective

oil coating on metal surfaces. Mating

surfaces of spindle and chuck MUST be

cleaned before assembly to prevent parts

from coming loose during operation.

Clamp Handle

Hex Key

Feed

Crank

5. Lift the Head Assembly (1) on top

of the column and slide it down

as far as it will go. Align the Head

Assembly with the Base Platform

(9). Tighten the set screw to

secure the head.

9. Secure upper pulley cover of head assembly by

installing locking knob.

Floor Standing Drill Press

5