Handling instructions

for GISMA connectors

HI

– 2007 - 001

Document: replaces

MV 2000-020,

MV 2000-030 and

MV 2005 - 011

First issue:

15.07.2008

Rev.-Index: -Z-

From:

29.07.2020

Copyright by:

GISMA GmbH

Page 14 of 44

In case, that the O-rings carrying assemblies are installed for more than 2 years to a structure

and then will be disassembled, we generally recommend to replace the O-rings.

We recommend changing the O-rings at latest after 5 years, if the O-rings are used as

directed.

For assemblies, which will only be installed once, our experience shows the estimated

lifetime may be double. For operating temperatures b5°C to +40°C, longer lifetimes

can be expected.

Defective clamps to be replaced.

Alignment

Put the plug onto the receptacle. Twist the connector until the keyway locks into place.

While tightening the locking sleeve with the one hand, simultaneously feed in the connector

with the other.

Mating

After tightening the locking sleeve by hand, screw it into the receptacle fitting using

corresponding wrenches.

For defined clamping torque refer to GISMA document “Torque

overview”.

Cathodic Protection

For titanium grade 5 connectors the cathodic protection is to be considered by the customer.

7.2.6. Test Port

Series 16 receptacles are equipped with test ports according to API specification 16D. The

integrity of the sealing of the mating and flange area could be tested.

The test ports should be sealed by the provided test port sealing plugs at all times.

For testing the sealing plugs will be replaced by a test port adapter and a test pressure pump will

be connected via Minimess hose. A pressure drop test according to customer specifications will

show the integrity of the sealing.

After the test, the sealing plugs must be carefully installed with clean and greased o-rings.

7.2.7. Pressure Balanced Oil Filled Hose (PBOF)

Series 16 plugs and receptacles are pressure proof from mating side as well as termination side.

This enables the usage of pressure balanced oil filled hose adapters and hoses (PBOF).

NOTE!

There are also receptacles for atmospheric junction boxes. Please make sure to use the

appropriate connector in your system.

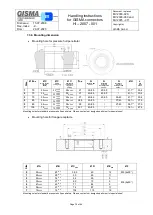

API specifications require boot seals as additional sealing system for PBOF. Boot seals must

match the wire diameter. Before applying the boot seal, a portion of GISMA grease EK-2 must be

applied inside the boot seal by use of a syringe.

GISMA highly recommends the usage of a boot seal fastening set. This fastening set keeps the

boot seals in place, restricts the bending radius and forms an extra oil reservoir.