Gilson Company, Inc.

Gilson Binder Ignition System: HM-378

Page 7

• Once the furnace reaches programmed setpoint

temperatures, it will maintain these temperatures

awaiting initiation of a Binder Ignition Test.

•

The furnace should be preheated for at least one hour

prior to testing a sample.

7.3 Performing a Typical Binder Ignition Test

1. Preheat hot-mix asphalt samples in a separate labo-

ratory oven to 100°C to facilitate even distribution of

the material in the sample basket. Even distribution

is essential to obtaining good test results.

2. Insure that a filter is properly installed and is not

clogged or blinded from previous tests to inhibit air

flow. Check the filter before each test.

3. Insure all program settings are correct, as noted

above.

4. Remove the pre-heated asphalt sample from the

laboratory oven and place on the sample basket,

distributing the material as evenly as possible. Even

distribution is key to obtaining good test results.

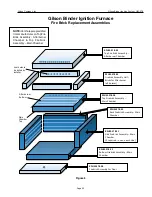

5. Place the sample basket with sample into the tray, and

place the cover over the basket. The cover must be

in place to prevent sample loss and possible damage

to the elements (see Figure 1 for details on sample

tray assembly).

WARNING!

ALWAYS use heat-resistant gloves and a face shield

when operating the furnace. Long hair should be tied

back or covered and loose clothing should be secured.

6. Using the loading fork provided, place the Sample Tray,

Basket, and Lid assembly into the furnace, centering

it on the hearth plates. Close the door, checking to be

sure that the locking pin has engaged the electronic

door lock mechanism.

7. Immediately press the <CONTINUE> key.

CONT will

appear on the display. The door will lock automatically

and the exhaust fan will turn on (if not on already).

WARNING!

DO NOT FAIL to press the <CONTINUE> key once

the sample is loaded. If this key is not pressed, the

sample will begin ignition with the door unlocked.

The automatic safety door lock will not be activated,

and DANGER of severe burns or injury will exist if

the door is opened.

8. The display will alternate between

bo (burn-out set

point) and the actual main chamber temperature. To

check after-burner temperature, press <2>.

AFTb will

alternate display with the after-burner temperature.

When the main chamber temperature reaches the

burn-out setpoint, the display will alternate between

TEST and the actual main chamber temperature. The

onset of ignition can be confirmed by observation of

flames in the chamber

FROM A DISTANCE via the

small hole in the front of the chamber.

WARNING!

NEVER leave the furnace unattended near the end

of firing! Gilson cannot guarantee the furnace against

over-firing even though the controller is automatic.

The operator assumes full responsibility for shutting

the furnace off at the proper time.

9. Once ignition occurs, the temperature of the main cham-

ber will rise a minimum of 20°C above burn-out set point

and is controlled only by the amount of oxygen allowed to

enter the furnace. During this time the controller cannot

maintain a constant temperature in the main chamber.

When ignition is nearing completion, the chamber will

return to the burn-out set point temperature, and the

Hold Time timer will begin. The display will alternate

between

HOLd and the time remaining. Once the time

has expired, the door lock will release automatically

and a beeping alarm will sound. Press <ANY> key

except <STOP> to silence the alarm. The controller

will automatically begin to bring the furnace to pre-heat

conditions in preparation for the next test.

NOTE: If the temperature does not rise at least

20°C above the burn-out set point, i.e., ignition does

not occur, the controller will wait 10 minutes before

proceeding to

CPLT and unlocking the door.

10. Carefully remove the Sample Tray Assembly the furnace

using the fork. Place it on the cooling stand, and remove

the cover. Check the sample to insure that is free of

coke. Coke is the solid residual of the binder after all

volatile material has been removed. If Coke remains,

replace the cover and return the assembly to the fur-

nace in “PREHEAT” mode until Coke is absent upon

re-inspection. Adjust program Hold Time for subsequent

tests as necessary. Larger sample quantities and larger

binder contents will require longer Hold Times.

NOTE: If it is necessary to return sample to furnace,

DO NOT press <CONTINUE>. This will initiate

another test cycle.