8

8. With a valve puller remove

the valve seat (37) and o-ring

(38) replace if worn. If exces-

sive pitting is seen, replace

the worn parts. Check valve

seat o-ring (38) for wear and

replace as necessary.

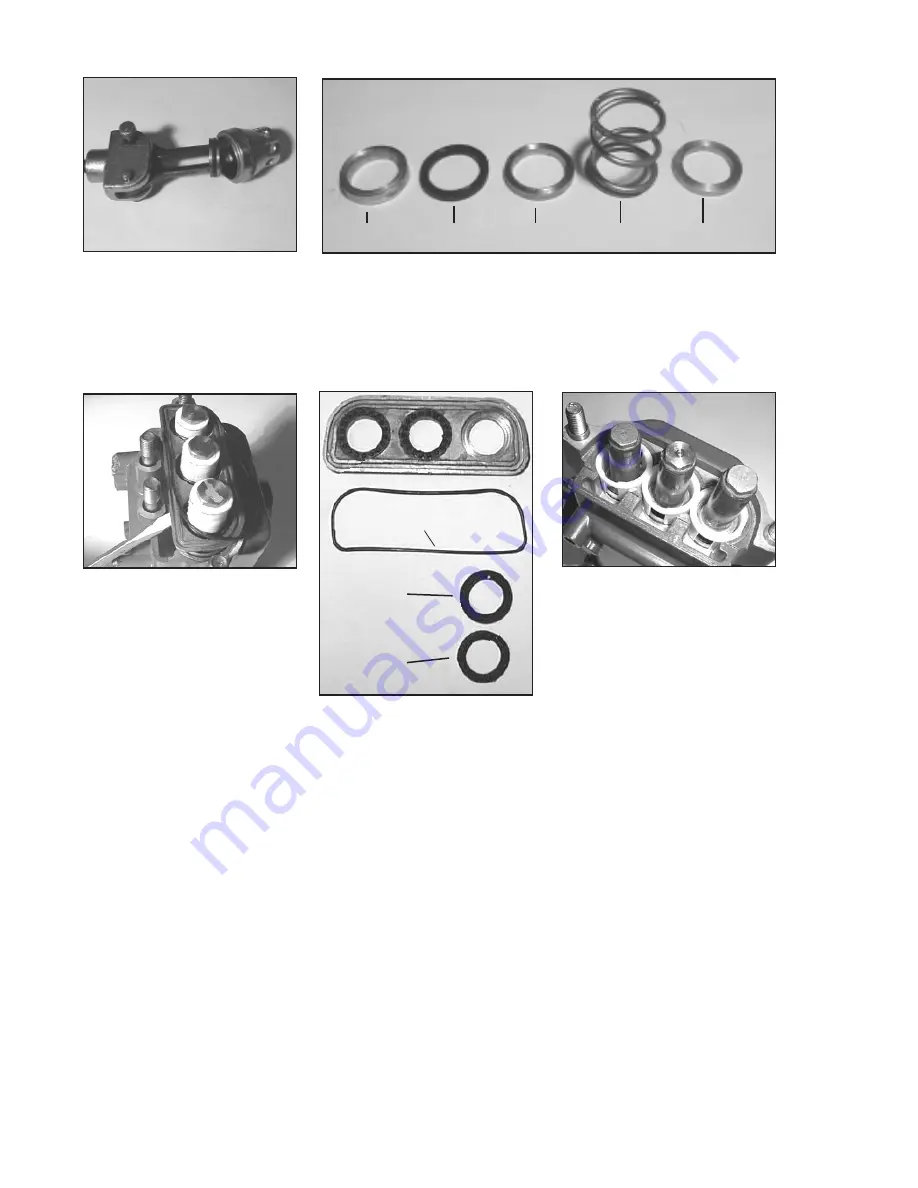

9. Remove the spacer (39A), pressure spring (33), support ring (32

or 31A for SP100HK), v-sleeve (31), and pressure ring (30), from

the manifold (29) and check for wear.

10.

With a flat headed screw-

driver remove the weep return

plate (48). Remove the o-ring

(49) and check for wear.

11. Inspect seals (50), seal sup-

port ring (51) and O-ring (49)

and replace as necessary.

49

50

51

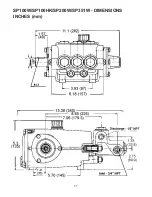

12.

Inspect ceramic plunger

(24A) tips for wear. If neces-

sary, replacement of the

ceramic plungers may be ac

-

complished by removing the

plunger bolt assemblies (24)

with a 13mm wrench. Ce-

ramic plungers should now

slide off the stainless steel

plunger base (22). Exces-

sive resistance to plunger

removal may be overcome

by heating the stainless steel

plunger base. This will melt

any excess loc-tite beneath

the ceramic plunger allowing

easy removal.

30

31

32

33

39A

REPAIR INSTRUCTION - SP100W/SP100HK/SP200W/SP351W PUMPS

31A for SP100HK