Page 21 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Water quality – Washer disinfectors

The quality of the water used in all stages of cleaning is important for good results.

The water used in each stage must be compatible with:

* The material that the washer disinfector is made of

* The chemicals used in the process

* Process requirements for the various stages of the process

The main factors for good water quality are:

Hardness

High hardness will cause limescale deposits in the washer disinfector, lead-

ing to poor cleaning results.

Ionic contaminants

A high concentration of ionic contaminants may cause corrosion and pitting

on stainless steel. Heavy metals such as iron, manganese or copper cause

instruments to tarnish.

Microbial contaminants

The water used should not increase the biological load on the equipment

that is being treated against micro-organisms and their residual products

which may cause fever-like symptoms when they get into the human body.

Sanitary chemicals

High concentrations of and high exposure to sanitary chemicals may cause

corrosion and pitting on stainless steel.

Getinge Disinfection AB therefore recommends that water used in the pre-rinsing,

washing and final rinsing phases should be of drinkable quality in accordance with

the guidelines .

Detailed information about acceptable water quality can be found in “Guidelines for

Drinking Water Quality, 3rd Edition” published by WHO.

Getinge Disinfection AB also recommends following local standards. RO (reverse-

osmosis) water (or similarly treated water) is used for the final washing/disinfection

phase. A typical specification for RO water is:

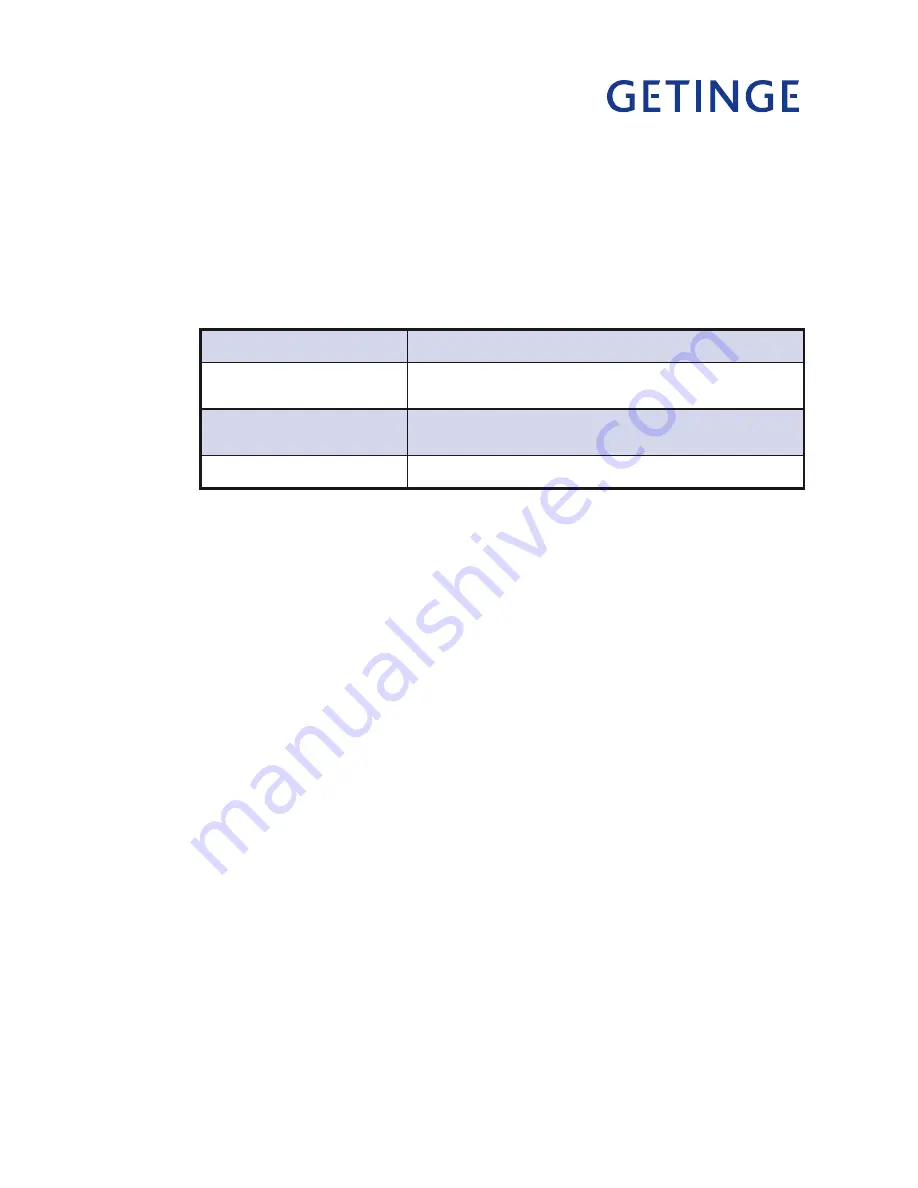

pH

5.5 till 8

Conductivity

<30 µs.cm

-1

TDS

<40 mg/l

Maximum hardness

<50 mg/l

Chlorine

<10 mg/l

Heavy metals

<10 mg/l

Phosphates

<0.2 mg/l as P

2

O

5

Silicates

<0.2 mg/l som SiO

2

Endotoxins

<0.25 EU/ml

Total number of micro-organisms

<100 per 100 ml

Further advice should also be obtained from the manufacturers of chemical and

medical equipment.

Where local standards are stricter than Getinge Disinfection AB’s recommendations,

they should be followed. Note that it is the customer’s responsibility to supply the

washer disinfector with suitable water.