16

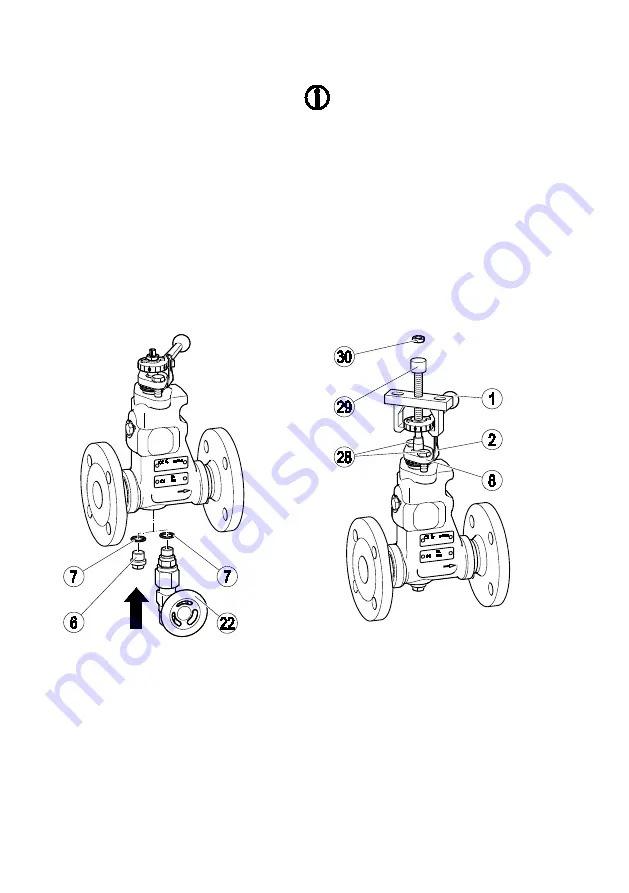

Installing the sampling valve

Remove the sealing plug (6).

Remove the sealing ring (7) from the body.

Insert the supplied sealing ring

A17 × 23 × 1.5 mm (7) in the hole.

Read and follow the instructions in the sampling

valve installation & operating manual.

Coat the thread and contact surfaces with

temperature-resistant lubricant.

The lubricant must have the same properties as

OKS 217.

Screw the sampling valve (22) into the hole in

the body with a torque of 130 Nm.

Positioning the control lever

In BA models, you can change the position

of the control lever by 180°.

You will find information on the required

tools on page 26.

Proceed as follows:

Remove the hex nuts (30) from the control lever.

Insert the puller (29) beneath the control lever.

Remove the control lever (1).

Remove the two stuffing box screws (28).

Remove the stuffing box gland (8).

Remove the dial (2).

Summary of Contents for BA 46

Page 3: ...Dimensions and weights 39 Pressure temperature ratings 43 Manufacturer s Declaration 45 ...

Page 19: ...19 Flow diagram for DN 15 to DN 32 capacity range up to 310 kg h ...

Page 20: ...20 Flow diagram for DN 15 to DN 32 capacity range up to 1 020 kg h ...

Page 21: ...21 Flow diagram for DN 15 to DN 32 capacity range up to 2 120 kg h ...

Page 22: ...22 Flow diagram for DN 40 and DN 50 capacity range up to 1 340 kg h ...

Page 23: ...23 Flow diagram for DN 40 and DN 50 capacity range up to 4 500 kg h ...

Page 24: ...24 Flow diagram for DN 40 and DN 50 capacity range up to 6 300 kg h ...

Page 39: ...39 Technical data Dimensions and weights BA BAE ...

Page 46: ...46 ...

Page 47: ...47 ...