Cleaning the LFGI- Heavy Duty (Rigorous)

Outside the LFGI

The outside of the LFGI can be cleaned at any time while the unit is closed and the

procedure does not require PPE additional to that normally used when operating the LFGI.

The stainless steel should be cleaned using a 70% alcohol solution or a solution specifically

designated for the cleaning of stainless steel. The acrylic front and side panels should be

cleaned with a soft cloth and a mild detergent, or a solution specifically designated for the

cleaning of acrylic surfaces.

It is important to

never

use abrasive cleaners or organic solvents on the acrylic components.

Additionally, the acrylic should not be cleaned with any solution stronger than 50% ethyl or

70% isopropyl alcohol. Do not use glass cleaner with ammonia.

Work from top to bottom. Do not remove or spray the prefilter at the top of the unit.

When cleaning the Airlock HEPA filter housings do not directly spray, instead spray the

cleaning agent into the cleaning cloth and wipe the outside surface off.

Raise the stand at least 3 inches from bottom position to wipe down the caster cross

supports.

NEVER spray cleaner of any type directly at the control panel located above the airlock.

Always spray onto a clean wipe and then wipe the surface, switches and knobs.

Inside the Airlock

1. Open the outer airlock door. Spray a clean wipe with disinfectant cleaner and wipe

the top HEPA filter protector from front to back moving left to right with

overlapping strokes.

2. Spray the wipe with cleaner and wipe the back HEPA filter protector from top to

bottom, moving left to right with overlapping strokes.

3. Spray the cleaner on the inside of the outer airlock door and remaining side and wipe

from top to bottom moving left to right with overlapping strokes.

4. Open the airlock door into the work area and slide the tray out into the work area.

Spray the floor of the airlock with disinfectant cleaner and wipe down.

5. Spray the tray with cleaner and wipe from left to right, and front to back with

overlapping strokes. Slide the tray back into the airlock.

6. Spray the inside of the inner airlock door and wipe from top to bottom moving left to

right with overlapping strokes. Close and latch the inner airlock door.

40

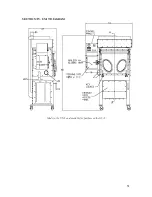

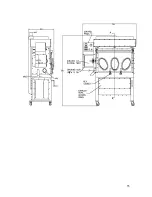

Summary of Contents for LFGI-3USP

Page 1: ...Laminar Flow LFGI CAI or CACI User Manual ...

Page 33: ...33 ...

Page 51: ...SECTION IV UNIT DIAGRAM Made in the USA and available for purchase on the GSA 51 ...

Page 55: ...55 ...

Page 59: ...59 ...

Page 63: ...Fig 2 Air recycle plenum connection tip removed 63 ...

Page 85: ... 863 248 2800 www sensocon com 20 Installation and Operation Manual Series A3 A4 ...