12

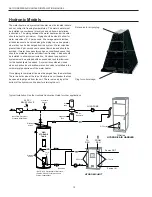

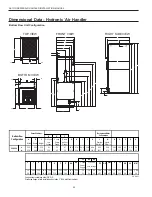

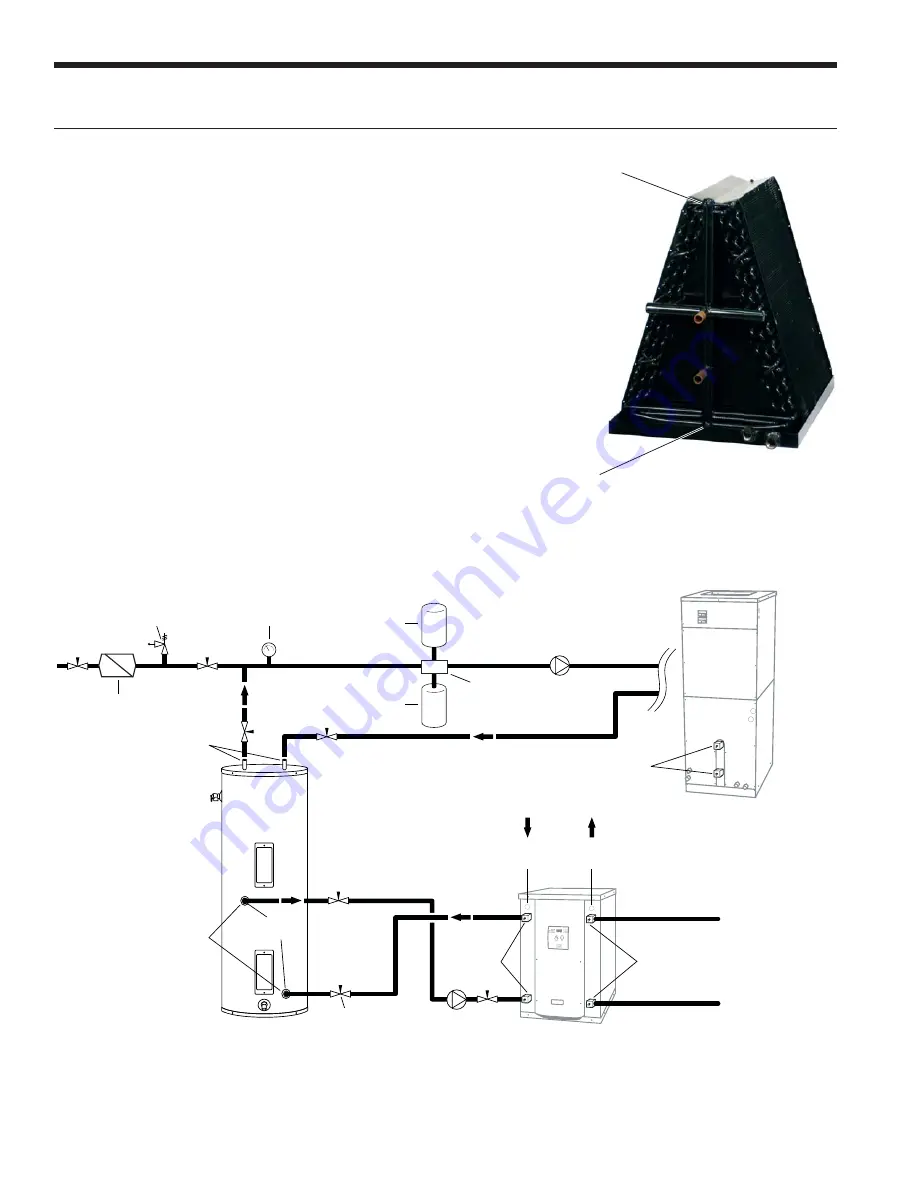

Hydronic Models

The water heater and hydronic air handler must be located indoors

and not subject to freezing temperatures. The water heater must

be installed in accordance to local codes and its own installation

instructions. The piping between the water heater and air handler

should be kept to a minimum. Piping should be sized to allow for

water velocities of 2’-4’ per second. At average water velocities,

air bubbles should be carried along the piping to an air separator

where they can be discharged from the system. Water velocities

greater than 4’ per second could cause flow noise and should be

avoided. If water lines pass through an unconditioned space they

should be protected to prevent them from freezing. Valves should

be installed to allow system isolation. All closed loop hydronic

systems must be equipped with an expansion tank to allow room

for the heated liquid to expand. A system is considered closed

when a check valve or backflow prevention valve is installed in the

cold water pipe upstream of the water heater.

Once piping is complete all air must be purged from the water lines.

There is a dole valve at the top of the hydronic coil header that can

be opened to purge air from the coil. There is also a plug at the

bottom of the hydronic coil header for draining the coil.

Plug for coil drainage.

Dole valve for air purging

Typical Installation. See the Hydronic Application Guide for other applications

ASTON SERIES AIR HANDLER INSTALLATION MANUAL

LOAD PUMP

Source OUT

P/T Ports

P/T Ports

Ball Valve

Dielectric

Unions

Dielectric

Unions

G Series

HYDRONIC UNIT

G Series

HYDRONIC AIR HANDLER

*NOTE: A 30 PSI pressure relief valve

(Part No: SRV30) should be used in

hydronic applications.

Ý

FPT

Expansion

Tank

Air

Vent

Pressure

Gauge

30 PSI

RELIEF VALVE

Air

Separator

TO

DSH

FROM

DSH

Back Flow Preventer /

Pressure Relief Valve

Source IN

GEO

STORAGE

TANK

P/T Ports