9

4.2 Temperature Correction

Because Geokon’s Vibrating Wire Displacement Transducers have a small coefficient of thermal

expansion, in many cases correction may not be necessary. However, if maximum accuracy is

desired, or the temperature changes are extreme (>10 °C), a correction may be applied based on

the following equation:

Dcorrected = ((R

1

- R

0

)

×

G) + ((T

1

- T

0

)

×

K)

Equation 3 - Thermally Corrected Deformation Calculation

Where;

R

1

is the current reading.

R

0

is the initial reading.

G is the linear gage factor.

T

1

is the current temperature.

T

0

is the initial temperature.

K is the thermal coefficient (see Equation 4).

The temperature coefficient of the mass or member to which the Crackmeter is attached should

also be taken into account. By correcting the transducer for temperature changes the temperature

coefficient of the mass or member may be distinguished.

Tests have determined that the thermal coefficient, K, changes with the position of the transducer

shaft. Hence, the first step in the temperature correction process is to determine the proper

thermal coefficient based on the following equation:

K = ((R

1

×

M)

+

B)

×

G

Equation 4 - Thermal Coefficient Calculation

Where;

R

1

is the current reading.

M is the multiplier from Table 3.

B is the constant from Table 3.

G is the linear gage factor from the supplied calibration sheet (Figure 6).

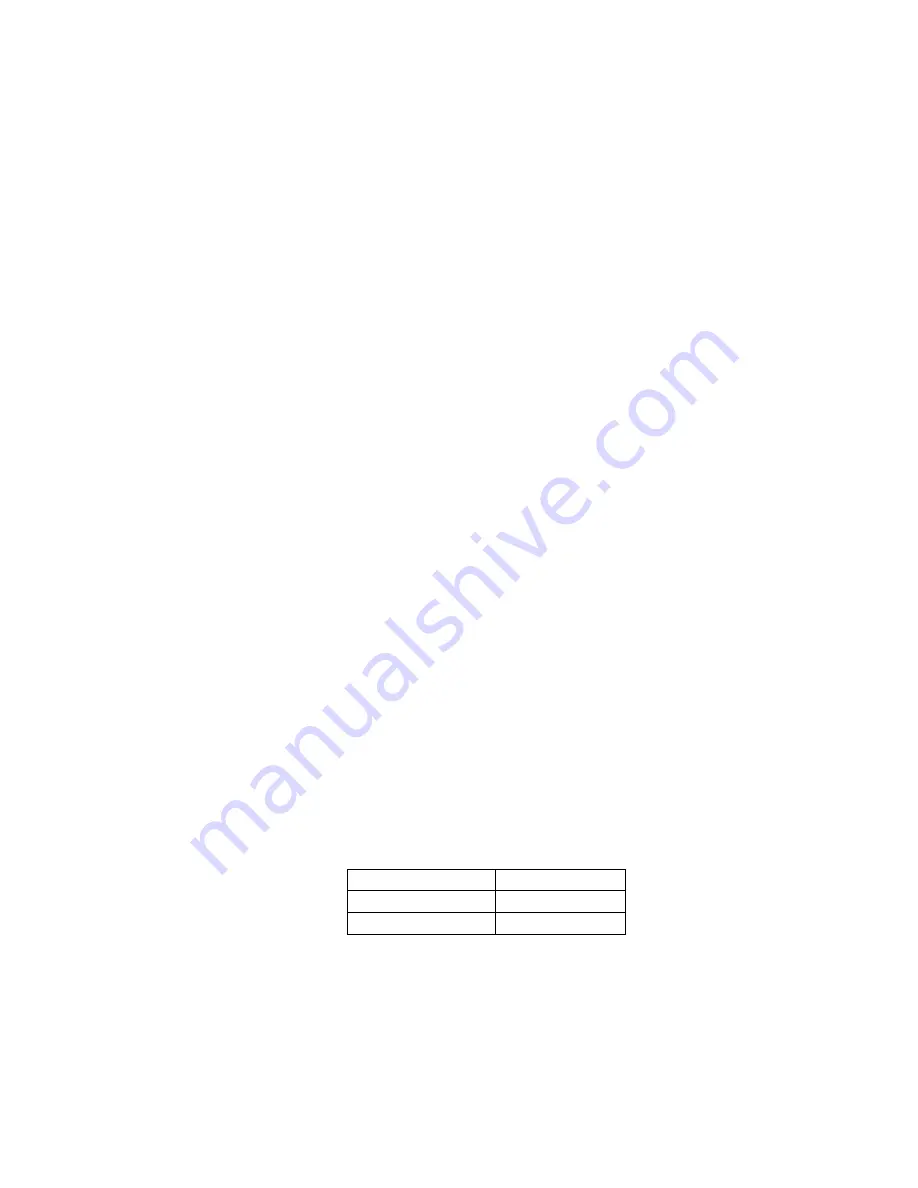

Model:

4422

Multiplier (M):

0.000471

Constant (B):

0.3562

Table 3 - Thermal Coefficient Calculation Constants

Summary of Contents for 4422

Page 2: ......

Page 4: ......

Page 17: ...11 Figure 6 Typical 4422 Monument Crackmeter Calibration Sheet ...