7

ENGLISH

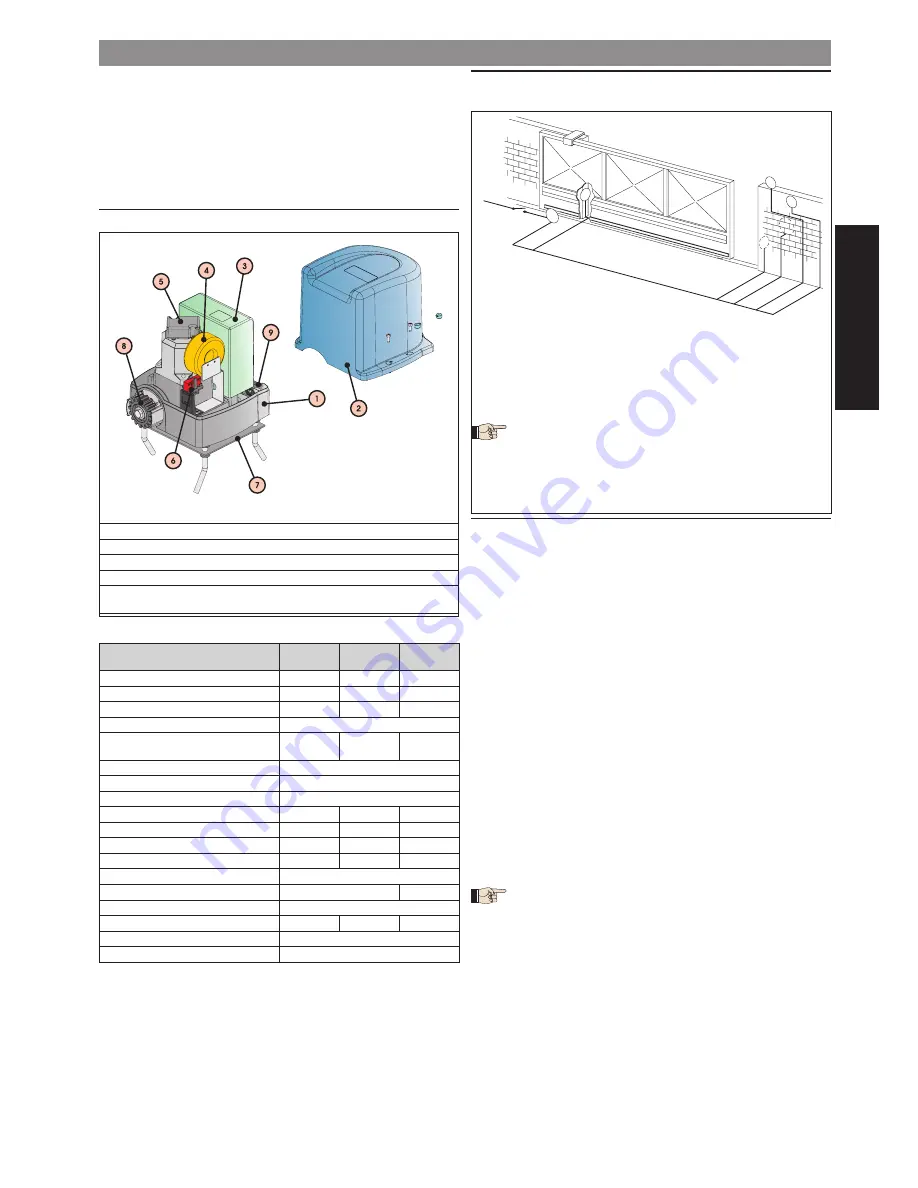

MILORD AUTOMATED SYSTEM

The MILORD automated system for residential sliding gates is an electro-

mechanical operator which transmits motion to the leaf through a pinion

gear suitably coupled to a rack fitted on the gate.

The non-reversing system ensures mechanical locking when the motor

is not operating and, therefore, installing a lock is unnecessary. A handy

release facility makes it possible to move the gate in the event of a power

cut or fault.

This operator has no mechanical clutch, and, therefore, requires a control

unit with electronic clutch.

In the “C” versions, MILORD operators have the electronic control unit built

into the operator body.

. DESCRIPTION AND TECHNICAL SPECIFICATIONS

t

eChniCal

speCifiCations

of

operators

Model

MILORD

5-5C

MILORD

424-424C

MILORD

8-8C

Power supply

230V~ 50Hz

24 Vdc

230V~ 50Hz

Absorbed power

350 W

70 W

500 W

Absorption

1.5 A

3 A

2.2 A

Electric motor rpm

1400

Thrust capacitor

10 µF 400V

/

12.5 µF

400V

Reduction ratio

1:25

Pinion

Z16

Rack

module 4

Max torque

18 Nm

13.5 Nm

24 Nm

Max thrust

45 daN

40 daN

65 daN

Thermal protection on winding

140°C

/

140°C

Use frequency

30%

100%

40%

Operating ambient temperature

-20°C +55°C

Operator weight

10 Kg

11Kg

Protection class

IP44

Max gate weight

500 Kg

400 Kg

800 Kg

Gate speed

12 m/min

Max gate length

15 m

1 Gearmotor

6 Magnetic sensor

2 Protective housing

7 Foundation plate

3 Control unit *

8 Pinion

4 Toroidal transformer **

9 Release device

5 Encoder **

* Standard supply only in “”C”” versions

** For MILORD 424C model only

1 Gearmotor

6 Magnetic sensor

2 Protective housing

7 Foundation plate

3 Control unit *

8 Pinion

4 Toroidal transformer **

9 Release device

5 Encoder **

* Standard supply only in “”C”” versions

** For MILORD 424C model only

Fig. 1

Fig. 1

2. ELECTRICAL SET-UP

(standard system)

3X1,5m

m

2

2

2

5

4

1

230V~

3x0,5 mm

2

2x0,5 mm

2

2x0,5 mm

2

2x1,5 mm

2

3x0,5 mm

2

3

3. INSTALLING THE AUTOMATED SYSTEM

3.. PRELIMINARY CHECKS

To ensure a correctly operating automated system, the structure of the

existing gate or gate to be built must satisfy the following requirements:

the weight of the gate must comply with the data in the technical spe-

cifications table;

sturdy, rigid gate structure;

smooth leaf surface (without any projections);

smooth, uniform gate movement, without any friction during the entire

travel;

no sideward leaf swings;

top and bottom sliding systems must be in excellent condition. It is prefe-

rable to use a ground-level guide with rounded groove to obtain reduced

sliding friction.

only two sliding wheels;

mechanical safety stops required to prevent the danger of gate derail-

ment; these stops must be firmly secured to the ground or to the ground-

level guide at about 40 mm beyond the travel limit position.

no mechanical closing locks.

We advise you to carry out the metalwork jobs before installing the auto-

mated system.

The condition of the structure directly influences the reliability and safety

of the automated system.

3.2. INSTALLING THE OPERATOR

Assemble the foundation plate as in Fig.3.

Dig a cavity for the foundation plate as shown in Fig. 4. The foundation

plate must be located as shown in Fig. 5 (right closing) or Fig.6 (left closing)

to ensure correct meshing between rack and pinion.

We advise you to place the plate on a cement base about 50 cm

off the ground (fig.7).

Lay the flexible pipes for routing the connection cables between gear-

motor, accessories and electrical power supply. The flexible pipes must

protrude by about 3 cm from the hole on the plate.

•

•

•

•

•

•

•

•

•

1.

2.

3.

Operator with built-in control unit (supply a suitable foundation plate)

Photocells

Key push-button

Flashing lamp

Receiver

1) To lay cables, use adequate rigid and/or flexible tubes.

2) Always separate connection cables of low voltage accessories

from those operating at 230 V~. To prevent any interference wha-

tever, use separate sheaths.

1.

2.

3.

4.

5.

Operator with built-in control unit (supply a suitable foundation plate)

Photocells

Key push-button

Flashing lamp

Receiver

1) To lay cables, use adequate rigid and/or flexible tubes.

2) Always separate connection cables of low voltage accessories

from those operating at 230 V~. To prevent any interference wha-

tever, use separate sheaths.

1.

2.

3.

4.

5.

Fig. 2

Fig. 2