Air Handler

23

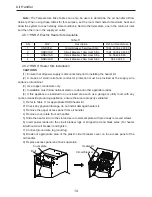

5. Installation Check and Trial Run

5.1 Checking Items after Installation

Table 15

Items to be checked

Problems might happen due to

improper installation

Check

Check if each parts of the unit have been

installed reliably.

The unit might fall off, vibrate or emit

noise.

Check if the unit has passed through

leakage test.

It may cause deficiency of cooling

(heating) capacity.

Check if the unit has been insulated

properly.

It may cause condensation and water

drop.

Check if the water can be drained fluently.

It may cause condensation and water

drop.

Check if the power voltage accords with

that on the nameplate.

Malfunction might happen and parts

might be burned.

Check if the wiring and pipe line has been

installed correctly.

Malfunction might happen and parts

might be burned.

Check if the unit has been earthed

soundly.

Hazard of electricity leakage

Check if the wiring conforms to the wire

gage.

Malfunction might happen and parts

might be burned.

Check if there is obstruction blocking the

air inlet/outlet.

It may cause deficiency of cooling

(heating) capacity.

Check if the piping length and

refrigeration charging volume has been

recorded

Uncertain about the refrigerant charging

volume.

Check if the piping connection and valves

have been set properly.

It may cause unit abnormality and

damage the unit.

Make sure there is no crack among air

return and supply pipe.

It may cause air leak, vibration and noise.

Check if the panel is mounted firmly.

It may cause air leak, vibration and

condensation.