4 - 14

Maintenance and Repair

4.10

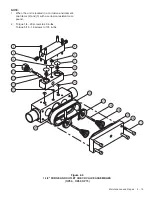

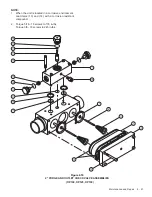

3" Purge Exhaust

Switching Valve Maintenance

(Model OP300 only)

WARNING!

Ensure that the dryer is de-energized, valve isolated,

and fully depressurized before attempting to remove

or disassemble any dryer component or subassembly.

Failure to do so may result in serious personal injury

and/or equipment damage.

Note: Removal of valve body [18] from the dryer manifold

is not required unless replacement of O-rings [19] or valve

body is necessary.

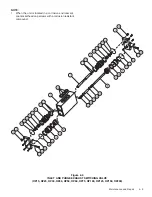

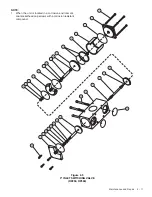

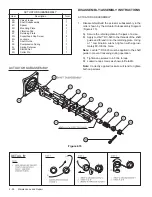

Note: Exploded view illustrates one-half of exhaust switch-

ing valve only. Disassembly of opposite half (not shown

exploded), is identical.

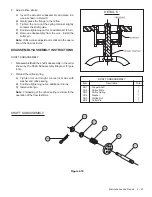

1.

Clean and inspect all valve hardware upon disassem-

bly. Replace all software and any hardware which ap-

pears damaged or abnormally worn.

2.

Clean and inspect valve seat located inside the valve

body [18]. As previously noted, this can be accom-

plished without removing the valve body [18] from the

dryer manifold.

3.

Apply an ultra-thin film of O-ring lubricant to items [3],

[6], [8], [12], [14] and [19] before reassembly.

4.

Apply a light coat of lubricant to the sockethead cap

screws, items (1) and (20). Hand tighten screws until

snug. Torque item (1) to 20 ft-lbs, and item (20) to

45 ft-lbs.

3" Switching Valve Components

Item

Description

Total

1

Sockethead Cap Screw

8

2

Valve Cover

2

3

O-Ring

2

4

Bonnet Cylinder

2

5

Locknut

2

6

Piston Seal

2

7

Valve Piston

2

8

O-Ring

4

9

Poppet Shaft

2

10

Rod Seal

4

11

Guide Sleeve

2

12

O-Ring

2

13

Valve Bonnet

2

14

O-Ring

2

15

Rod Scraper

2

16

Valve Poppet

2

17

Machined Bolt

2

18

Valve Body

1

19

O-Ring

2

20

Sockethead Cap Screw

4