19

9 PARTS BREAKDOWN (Continued)

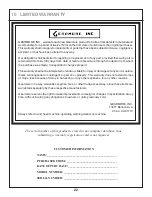

REF #

QTY.

PART NO.

DESCRIPTION

1a

1

620.037

Axle

w/Bushing

2a

2

620.007

Wheel 20 x 10.00 - 8 D266

3a

8

300.006

Hexagonal Head Screw 12 x 30

4a

1

325.017

Release

Bushing

5a

9

300.003

Hexagonal Head Screw 10 x 25

6a

5

303.025

Washer 10 x 30

7a

1

326.007

Key 6 x 6 x 30

8a

4

301.013

Self Locking Nut M10

9a

1

303.019

Washer 14 x 42 x 3

10a

1

325.018

Rotary

Bushing

11a

1

610.043

S.S. Spreading Disc

12a

6

601.026

Stainless

Steel

Vane

13a

12

300.107

S.S. Cup Square Screw 8 x 16 (QH3 UNI 5731)

14a

4

301.012

Galvanized Nut M8

610.044

S.S. Spreading Disc w/S.S. Vanes & Bolts & Nuts

15a

1

325.001

Disc's Upper Bushing

16a

1

305.001

Spring Pin 8 x 40

17a

1

305.003

Spring Pin 5 x 40

18a

8

303.007

Galvanized Washer 8 x 17 UNI 6592

19a

4

300.029

Galvanized Hexagonal Head Screw 8 x 20 UNI 5739

20a

1

330.005

Entrainer

21a

1

610.011

Stainless Steel Adjustment Disc

22a

3

303.012

Thickening Washer 56 x 70 x 0.5

23a

1

303.031

Disc Spring 79.5 x 55.5 x 0.8

24a

1

313.012

Retaining Ring M55 UNI 7435

25a

2

304.053

Rubber Washer 5 mm Thick

26a

1

620.009

Metal

Ring

27a

1

619.033

Lower

Agitator

619.003 Lower

Agitator

Kit

w/Plate

28a

6

300.037

Galvanized Hex Head Screw 6 x 20 UNI 5739

29a

2

303.014

Galvanized Washer 6 x 12 UNI 6592

30b

1

609.031

Hopper PTB 560

31a

8

300.043

Galvanized Cup Square Screw 10 x 25 UNI 5739

32a

16

301.010

Galvanized Nut M10 5588

33a

29

303.015

Galvanized Washer 10 x 20 UNI 6592

34a

1

613.020

Right

Frame

Tube

35a

1

613.021

Left

Frame

Tube

36a

4

612.003

Frame Rubber Cap Dia. 75 mm

37a

8

303.013

Galvanized Washer 8 x 24 UNI 6593

38a

1

639.013

Iron Rear Shield