A B C

A B C

A B C

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

0.50 1.00 2.50

0.40

0.35

0.30

0.25

0.80

0.70

0.60

0.50

2.00

1.75

1.50

1.25

48

24

60

30

12

80

40

16

96

48

m m

n/ 1 ″

mm

0.035 0.07 0.175

0.045 0.09 0.225

0.05 0.10 0.25

0.06 0.12 0.30

0.075 0.15 0.375

Pic

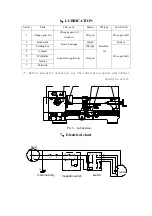

5、Feeding & Threading Tablet

When change metric threading to imperial threading, besides the

indications shown on the tablet, you are required to change Gear A

from teeth 34(teeth 36) to teeth 36 (teeth 34).

)

Carriage

:

Handle 8 is for longitudinal and cross feeding. Press down for cross feeding and

up for longitudinal, the middle is neutral position. When handle 8 at neutral

position, rotate handwheel 5 and 6 can also achieve longitudinal/cross movement

of toolpost. Press down handle 9, close the halfnut, the toolpost shall make

threading. Handle 8 and 9 can be inter-locked.

)

Saddle and toolpost

:

Handle 7 is for locking the toolpot, handle 10 is for moving the small carriage

and handle 6 for moving working table.

)

Tailstock

:

Handle 11 is for locking the sleeve in tailstock. Releasing handle 11, rotate

handle 13, you can get out sleeve; handle 12 is for locking the tailstock.

z

Maintenance

:

)

Making lubrication as per request before operation.

)

Clean the chips on bedway, saddle, toolpost to avoid strain.

)

The operator shall strictly make the operation as per regulations to

avoid damage of the lathe and human safety.

)

Never stop/brake the lathe by hands.

)

No setting of tools and other objects on the headstock, toolpost and

guidewawy.