2064-9001-001

/

1010

29

Westfalia Separator

®

1.5.9 Maintenance and repair

Unfavourable operating conditions may require shorter maintenance intervals.

The factors listed below are unfavourable because they either attack the sepa-

rator material directly or impair the lubrication/cooling system:

•

Aggressive product (chemical or physical)

•

High product temperature

•

Product with grease-decaying properties

•

Environment: Temperature, dust, vapours

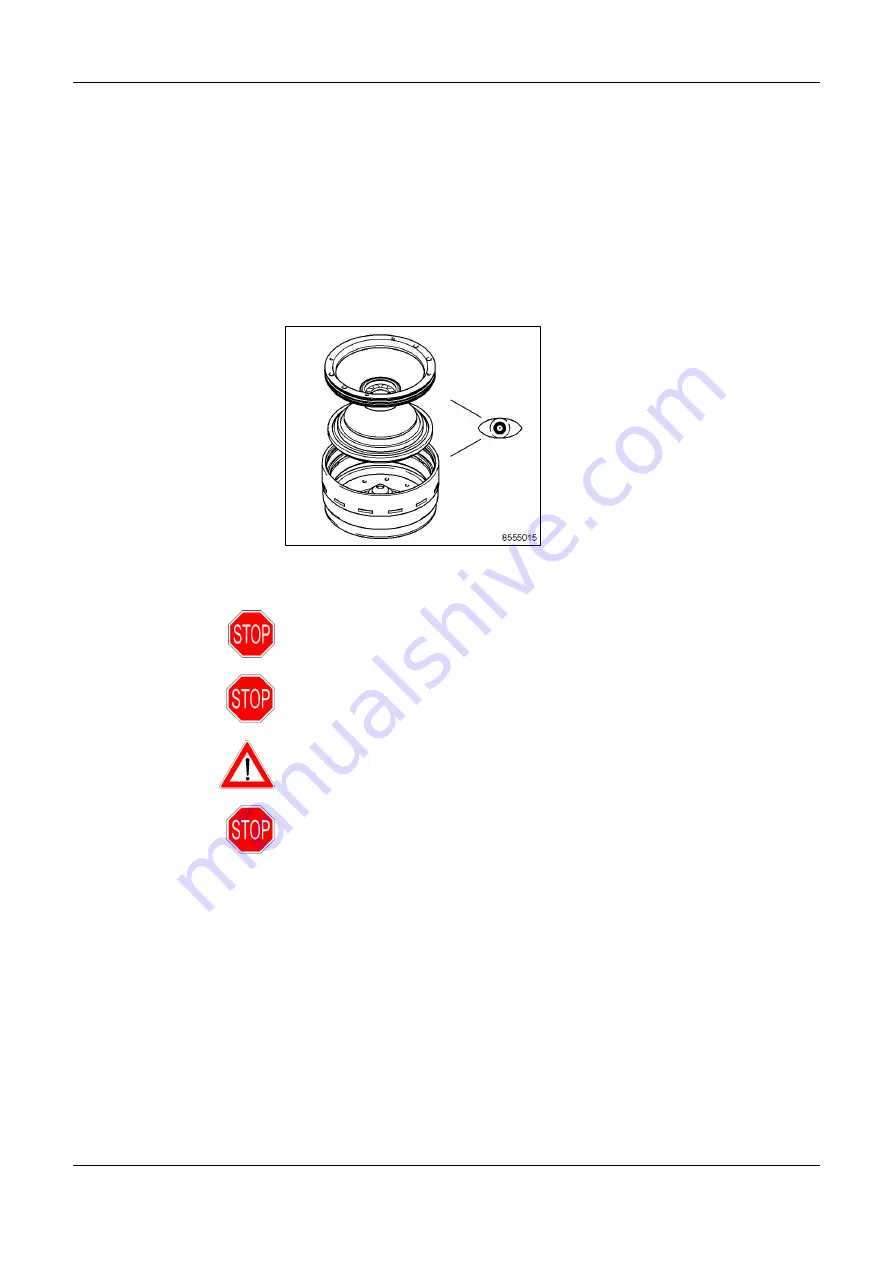

Particularly high-stressed separator

parts like

–

Bowl lock ring,

–

bowl bottom,

–

bowl top and

–

other bowl parts with a large outer

diameter

must be checked regularly to assure

safe and efficient operation.

Fig. 45

Timely maintenance of the separator and replacement of worn or damaged ma-

chine parts is essential for safe operation of the machine.

Use only genuine spare parts from Westfalia Separator. Otherwise, safety

risks may arise (see section

Carry out the required cleaning thoroughly.

One-sided solid deposits in the bowl cause severe unbalance!

Maintenance and repair work may only be carried out to the extent described in

this instruction manual.

Maintenance and repair work not described in this manual may only be

carried out by the manufacturer or by "repair shops" authorized by the

manufacturer.

We, therefore, recommend in your own interest to have your separator in-

spected by our service engineers at regular intervals. These checks help to

maintain the operating safety and avoid unexpected downtime.

Summary of Contents for OSE 20-0136-067

Page 40: ...40 2064 9001 001 1010 Westfalia Separator 2 2 Section through separator Fig 59 ...

Page 170: ...170 2064 9001 001 1010 Westfalia Separator 4 6 Drive Fig 247 Exploded view of the drive ...

Page 208: ...208 2064 9001 001 1010 Westfalia Separator 4 14 Special tools Fig 328 ...