D

GB

F

E

I

Ru

13

09958-12.2014-DGbFEIRu

5

|

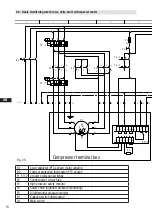

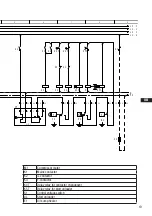

Electrical connection

5 Electrical connection

DANGER! High voltage! Risk of electric shock! Only carry out work when the

electrical system is disconnected from the power supply!

INFO!

Connect the compressor motor in accordance with the circuit diagram

(see inside of terminal box).

Use suitable cable entry point of the correct protection type

(see name plate) for routing cables into the terminal box.

Insert the strain reliefs and prevent chafe marks on the cables.

Compare the voltage and frequency values with the data for the mains

power supply.

Only connect the motor if these values are the same.

5.2 Standard motor, design for direct or part winding start

Designation on the name plate

Sticker on the terminal box

Y/YY

Compressors with this marking are suitable for direct or partial winding start. The motor winding is

subdivided into two parts: Partial winding 1 = 66% and part winding 2 = 33%. This winding division

reduces the start-up current needed for a part winding start to approx. 65% of that for a direct start.

INFO!

A mechanical unloaded start with bypass solenoid valve is

not required.

5.1 Information for contactor and motor contactor selection

All protection devices and switching or monitoring units must be fitted in accordance with the local

safety regulations and established specifications (e.g. VDE) as well as with the manufacturer’s infor

-

mation.

Motor protection switches are required!

Motor contactors, feed lines, fuses and motor

protection switches must be rated on the basis of the maximum working current (see name plate).

For motor protection use a current-dependent and time-delayed overload protection device for moni-

toring all three phases. Set the overload protection device so that it must be actuated within 2 hours,

if there is 1.2 times the max. working current.