11

09716-01.2013-DGbFEIT

rCn

D

GB

F

E

I

TR

CN

4

|

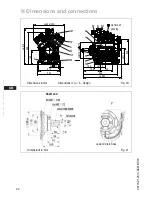

Compressor assembly

4.1 Setting up

4.2 Maximum permissible inclination

A

max. 30°,

max. 2 minutes

a

max. 15°,

continuous

operation

ATTENTION! Poor lubrication can damage the compressor. Respect the stated

values.

INFO!

New compressors are factory-filled with inert gas (3 bar nitrogen).

Leave this service charge in the compressor for as long as possible

and prevent the ingress of air.

Check the compressor for transport damage before starting any

work.

Fig. 8

Fig. 9

Transport and suspension unit on the eyebolt (Fig . 8) or direct on the discharge line valve

(Fig. 9).

Fittings (e.g. pipe holders, additional units etc.) on the compressor are permissible only

following consultation with Bock.

Setup on an even surface or frame with sufficient load-bearing capacity. Use all 4 fastening

points.

Correct setup of the compressor and mounting of the belt drive are decisive for running comfort,

operating safety and the service life of the compressor.

A

a

A

a

WARNING! Move compressors only with hoists that have adequate load-bearing

capacity.

A

a

A

a

Fig. 10