Critical Power

Modifications reserved

Page 33/53

GE_UPS_ISG_TLE_SUL_40K_M15_1US_V010.docx

Installation Guide TLE Scalable Series 40 - 150 UL S1

4.8.2

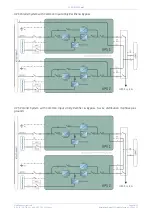

TLE Scalable Series 40 - 150 - Power connection with Dual Input Utility

NOTE !

Connect a single input

Neutral

to

Bypass Utility

(inside the UPS, common

Neutral

for

Bypass

and

Rectifier)

.

Fig. 4.8.2-1 TLE Scalable Series 40 - 150 -

Power connection with Dual Input Utility

Power connection cables are connected to bus bars using M8 bolts.

The bolts of the connection cables must be tightened with a torque wrench at 195 Lb-in / 22 Nm.

Dual Input Utility - Rectifier / Bypass

L1-1

Rectifier phase A (L1)

L1-2

Bypass phase A (L1)

L2-1

Rectifier phase B (L2)

L2-2

Bypass phase B (L2)

L3-1

Rectifier phase C (L3)

L3-2

Bypass phase C (L3)

PE

Ground Input Utility

N

Neutral Input Utility

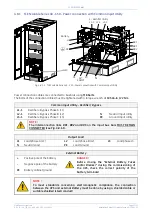

NOTE !

The interconnection links

BR1

,

BR2

and

BR3

on the input bus bars MUST BE

REMOVED (see

Fig. 4.8.2-3)

.

Output Load

L1

Load phase A (L1)

L2

Load phase B (L2)

L3

Load phase L3

N

Neutral Load

PE

Load Ground

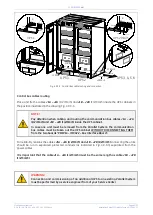

External Battery

+

Positive pole of the battery

DANGER !

Before closing the "

External Battery Fuses

end/or Breaker

" during the commissioning of

the UPS, check the correct polarity of the

battery terminals!

-

Negative pole of the battery

PE

Battery cabinet ground

NOTE !

To meet standards concerning electromagnetic compliance, the connection

between the UPS and external

Battery

must be done by using a shielded cable or

suitable shielded (steel) conduit!

Battery

_

+

Q1

PE

L1 L2

Load

L3

L1-1 L2-1 L3-1

1 - Rectifier Utility

L1-2 L2-2 L3-2

2 - Bypass Utility

BR1

BR2

BR3

N

INTERCONNECTIONS LINKS

BR1, BR2 and BR3

MUST BE REMOVED

EP

O

EP

O

-

+

XA

Q1

TLES

_UL

_04

0-15

0_S

1_U

PS c

onn

ecti

on s

epa

rate

_01

US