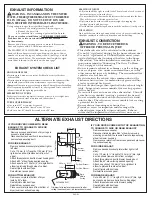

ALTERNATE EXHAUST DIRECTIONS

PAGE 3

Left knockout

Bottom

knockout

Right knockout

For Rear Exhaust

For Side Exhaust

Rigid

Metallic

Ducting

Cut Here

EXTENSION DUCT

It is importat to replace the ground clip after

cutting the exhaust duct, (on rear exhaust model).

Blower

Front of dryer

152 mm

295 mm

115 mm

203 mm

(8”)

89 mm

(3½”)

(4½”)

(11½”)

6”

FOR BOTTOM EXHAUST:

Remove cover plate at bottom of dryer.

Install a 90° elbow.

Seal all joints with duct tape.

Reinstall rear access panel.

Place cover plate (removed from bottom of

dryer) over rear exhaust opening.

FOR SIDE EXHAUST:

Remove desired knockout plate (either right or

left side).

Cut a 115 mm (4 ½”) length of 100 mm (4”) dia

rigid duct as shown (remove burrs from cut

edge).

Attach this extension duct to blower housing duct.

Attach a 90° elbow facing desired opening.

Attach a section of 100 mm (4”) dia, rigid duct to

elbow to protrude through side of cabinet.

Seal all joints with duct tape.

Reinstall rear acces panel.

IF YOUR DRYER COMES WITH REAR

EXHAUST, TO CHANGE TO SIDE OR

DOWN EXHAUST:

Remove access panel at back of dryer to gain

access to internal ducts.

Disconnect duct exhaust from blower housing

(remove tape securing duct).

IF YOUR DRYER COMES WITH TOP EXHAUSTING,

TO CHANGE TO SIDE OR REAR EXHAUST:

Remove rear access panel.

Disconnect retaining plate & 90° elbow by removing

mounting screw from the chassis & remove tape securing

elbow to blower hounsing.

Remove cover plate from rear access panel and place over

top exhaust opening.

FOR SIDE EXHAUST:

Remove desired knockout plate (either right or left

side).

Cut a 115 mm (4 ½ “) lenght of 100 mm (4”) dia, rigid

duct as shown (remove burrs from cut edge).

Attach this extension duct to blower housing duct.

Attach the 90° elbow facing desired opening.

Attach a section of 100 mm (4”) dia, rigid duct to

elbow to protude thru side of cabinet.

Seal all joints with duct tape.

Reinstall rear access panel.

FOR REAR EXHAUST:

Cut a 295 mm (11 ½ “) length of 100 mm (4”) dia, rigid

duct as shown (remove burrs from cutting edge).

Attach this extension duct to blower housing.

Seal all joints with duct tape.

Reinstall near access panel.

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entry of birds or

other wildlife.

• Termination should present minimal resistance to the exhaust air flow

and should require little or no maintenance to prevent clogging.

•

Never

install a screen in or over the exhaust duct. This could cause lint build up.

• Wall caps must be installed at least 12 in. above ground level or any other

obstruction with the opening pointed down.

SEPARATION OF TURNS

For best performance, separate all turns by at least 4 ft. of straight duct,

including distance between last turn and exhaust hood.

TURNS OTHER THAN 90º

• One turn of 45º or less may be ignored.

• Two 45º turns should be treated as one 90º turn.

• Each turn over 45º should be treated as one 90º turn.

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male end of each section of

duct must point away from the dryer.

• Do not assemble the ductwork with fasteners that extend into the duct.

They will serve as a collection point for lint.

• Duct joints can be made air and moisture-tight by wrapping the

overlapped joints with duct tape.

• Horizontal runs should slope down toward the outdoors ½ inch per foot

INSULATION

Duct work that runs through an unheated area or is near air conditioning

should be insulated to reduce condensation and lint build-up.

EXHAUST INFORMATION

WARNING - IN CANADA AND IN THE UNITED

IS 4 IN (102mm). DO NOT USE DUCT LONGER

STATES, THE REQUIRED EXHAUST DUCT DIAMETER

THAN SPECIFIED IN THE EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reduce the dryer life.

• Accumulate lint, creating a potential fire hazard.

The MAXIMUM ALLOWABLE duct length and number of

bends of the exhaust system depends upon the type of duct,

number of turns, the type of exhaust hood (wall cap), and all

conditions noted below. The maximum duct length for rigid

metal duct is shown in the table on the next page.

The correct exhaust installation is YOUR RESPONSIBILITY.

Problems due to incorrect installation are not covered

by the warranty.

Remove and discard existing plastic or metal foil transition

duct and replace with UL listed transition duct.

EXHAUST CONNECTION

WARNING - TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

•

•

•

•

•

•

•

•

•

•

This clothes dryer must be exhausted to the outdoors.

Use only 4” rigid metal ducting for the home exhaust duct.

Use only 4” rigid metal or UL-listed flexible metal (semi-

rigid or foil-type) duct to connect the dryer to the home

exhaust duct. It must be installed in accordance with the

instructions found in “Connecting The Dryer To House

Vent” on page 4 of this manual.

Do not terminate exhaust in a chimney, a wall, a ceiling, gas

vent, crawl space, attic, under an enclosed floor, or in any

other concealed space of a building. The accumulated lint

could create a fire hazard.

Never terminate the exhaust into a common duct with a

kitchen exhaust system. A combination of grease and lint

creates a potential fire hazard.

Do not use duct longer than specified in the exhaust length

table. Longer ducts can accumulate lint, creating a poten-

tial fire hazard.

Never install a screen in or over the exhaust duct. This will

cause lint to accumulate, creating a potential fire hazard.

Do not assemble ductwork with any fasteners that extend

into the duct. These fasteners can accumulate lint, creating

a potential fire hazard.

Do not obstruct incoming or exhausted air.

Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspected and cleaned at least once a year.