SecoGear 24kV-27kV Air Insulation Switchgear

21

Inspection and maintenance

Summary

After the process of installation and testing, the switchgear

is available to use. Timely and proper maintenance can keep

the switchgear trouble-free and can prolong the life of the

switchgear as long as possible.

The maintenance work must be carried out by certified persons

who are familiar with the related operations of the switchgear

and understand relevant IEC and other local safety rules and

important guides established by other technical departments

as well. Allow a GE representative to assist when the switchgear

and its components need to be repaired. Users should think

about the operating environment and the operation frequency

when developing maintenance rules. Usually the inspection of

some equipment / components (such as wearable parts) and

the maintenance intervals (maintenance period) depend on

the running time, operating frequency and the number of short

circuit cycles. The maintenance period of other parts depends on

the working situation, the degree of the load and environmental

impact (including pollution and corrosive gasses).

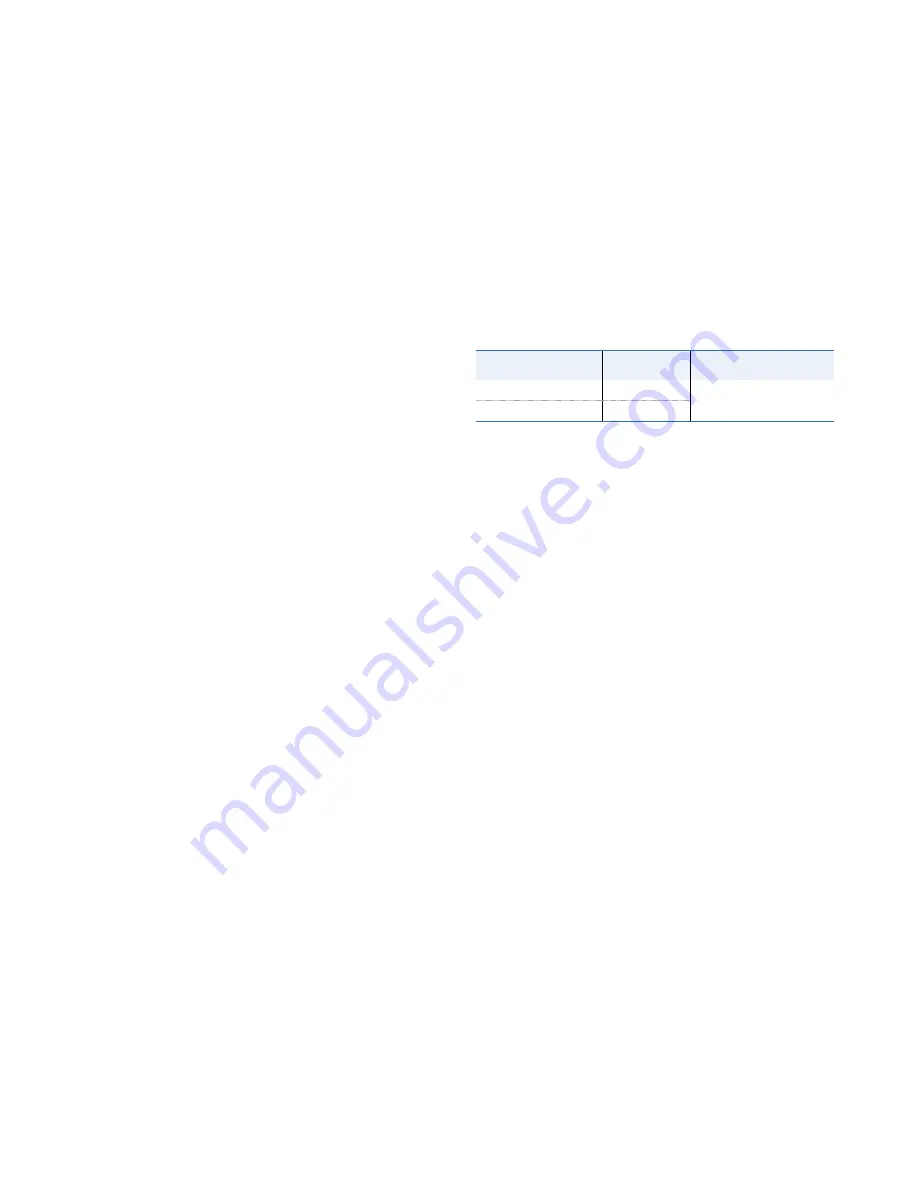

Inspection and maintenance interval

The maintenance interval determined by operating conditions of

the switchgear depends on the operating mode, the operating

number of rated current and short circuit current, environment

temperature and pollution.

The recommending maintenance interval is showed in the

following table:

maintenance content

interval(years) according to the operation

cycle of circuit breaker

inspection

2~3

1)

5000

3)

care and maintenance 2~3

2)

1) Recommended shorter interval years when operated in very

severe running conditions.

2) According to inspection results.

3) Refer to the VCB manual.