Nuova Via di Piano Comprensorio Vulcano

Sesto San Giovanni, MI 20099 Italy

Tel. 02-24105.001

IS 2653 GB

Page

15

of

18

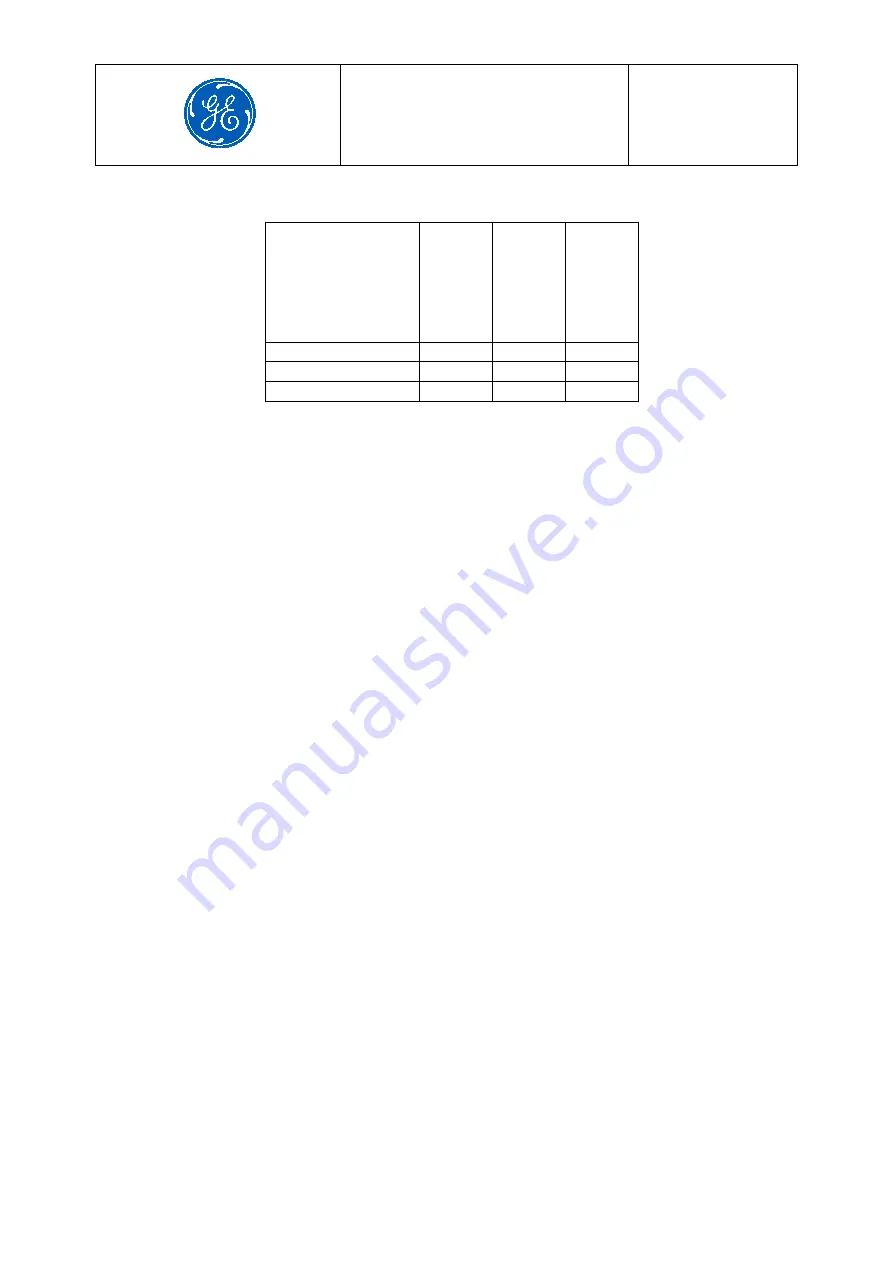

Time base

V

is

u

a

l

in

s

p

e

c

ti

o

n

U

V

c

a

m

e

ra

a

n

d

in

fr

a

re

d

e

x

a

m

in

a

ti

o

n

W

e

tt

a

b

il

it

y

6 Months

X

1 Year

X

X

When plant is off

X

X

Table 2 – Composite insulator maintenance plan

Visual inspection:

Carefully check that the composite insulators sheds do not show any mechanical damages and significant

tracking or erosion due to electrical stress.

Visually evaluate also the pollution status and identify the areas of concentrated contamination.

Take note of the position of the areas of evidences, to be carefully analysed and taken under control during

future inspections. In case of evidence of incipient erosion / tracking, plan an immediate washing action.

UV camera and infrared examination:

Scan all the surface of the composite insulators with an UV camera to identify possible areas of intense UV

emissions on the sheds, on the toroids and the incoming line cables. To perform this test, the camera must be

properly set in order to avoid false signals and background noise.

In addition, an infrared scan on the line terminal and the incoming cables can reveal incipient hot spots

phenomenon that can evolve into a serious damage on the electrical connection and then of the bushing itself.

In case of significant variation of the UV and IR emission, plan the following actions:

UV emission: Immediate washing action on the interested part, in the meanwhile control all electrical

connections.

IR emission:

Immediate control of all electrical connections.

Wettability:

The hydrophobicity of the composite insulator can be checked by following the methodology described in IEC

TS 62073 – 2003 Guidance on the measurement of wettability on insulator surfaces.

The simplest way to assess the wettability is the Method C - Spray method.

Wettability level up to WC4 is acceptable for normal operation. In case of further degradation of wettability level

(WC5 and WC6) proceed with an accurate washing and drying and then repeat the test.

If wettability remains low but there are no evidences of tracking or erosion keep the bushing in operation but

follows the intensive maintenance plan of

Table 3

.