Installation Instructions

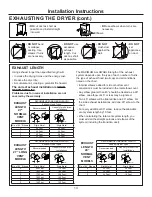

MOBILE OR MANUFACTURED

HOME INSTALLATION

3

• Installation MUST conform to the MANUFACTURED

HOME CONSTRUCTION AND SAFETY

STANDARD, TITLE 24, PART 3280 or STANDARD

FOR MOBILE HOMES CAN/CSA-Z240 MH, or,

when such standards are not applicable, with

AMERICAN NATIONAL STANDARD FOR MOBILE

HOME, ANSI/NFPA NO. 501B.

• The dryer MUST be vented to the outdoors.

• The exhaust vent MUST be securely fastened to a

non-combustible portion of the mobile home.

• The vent MUST NOT be terminated beneath a

mobile or manufactured home.

• The vent duct material MUST BE METAL.

• KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

• The vent MUST NOT be connected to any other

duct, vent or chimney.

•

DO NOT

use sheet metal screws or other

fastening devices which extend into the interior of

the exhaust vent.

• Provide an opening with a free area of at least 25

square inches for introduction of outside air into

the dryer room.

• See the sections for electrical connection information.

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Failure to do so can result in death, explosion, or fire.

• The dryer MUST be vented to the outdoors.

• Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0” either side

0” rear

1” front

1” top

• Consideration must be given to provide adequate

clearance for installation and service.

• Closet doors must be louvered or otherwise ventilated

and doors must contain a minimum of:

72 square inches of open area for GUD24 series

models

120 square inches of open area for GUD27 and

GUV27 series models

NOTE:

WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, THE CONFIGURATION

OF THE DUCTING MAY REQUIRE GREATER THAN

3” OF REAR CLEARANCE.

Gas Dryers Only:

• No other fuel burning appliance shall be installed in

the same closet as a gas dryer.

• The dryer must be disconnected from the gas

supply piping during pressure testing at pressures

greater than ½ psi (3.5 kPa).

• A 1/8 inch NPT minimum plugged tapping,

accessible for test gauge connection, must be

installed immediately upstream of the gas supply

connection to the dryer.

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air opening are: 0” both sides, 0” rear and 1” top.

Consideration must be given to provide adequate

clearance for installation and service.

INSTALLATION REQUIREMENTS

LOCATION

This appliance must be installed on firm flooring to minimize

vibration during spin cycle. Concrete flooring is best, but

wood base is sufficient, provided floor support meets FHA

standards. This appliance should not be installed on rugs.

DO NOT Install the Appliance:

1.

In an area exposed to dripping water or outside

weather conditions. The ambient temperature should

never be below 60°F (15.6°C) for proper operation.

2.

In an area where it will come in contact with curtains

or drapes.

3.

On carpet. The floor

MUST

be a hard surface with

a maximum slope of 1/2″ per foot (1.27 cm per 30

cm). To make sure the appliance does not vibrate or

move, you may have to reinforce the floor.

NOTE:

If floor is in poor condition, use 3/4″ impregnated

plywood sheet solidly attached to existing floor covering.

- Explosion Hazard

WARNING