9

Temperature Selector Switch

The rotary temperature selector switch, one of the

controls on the model DBL333, allows the customer

to select different temperature settings for drying.

The switch contains a 3K ohm resistor on the electric

model and a 2.4K ohm resistor on the gas model.

On the “Medium” setting, the selector switch

activates a control thermostat bias heater, which is

in series with the resistor on the switch. To check

the switch, disconnect power, remove the wires from

the switch and check

for continuity. With the

switch set on “Regular”

setting, there should be

continuity only between

terminals 1 and 2. On

the “Medium” setting,

there should be

continuity only between

terminals 3 and 4. On a “Fluff” setting, there should

be no continuity between either set of terminals.

Resistor

3

5

2

1

4

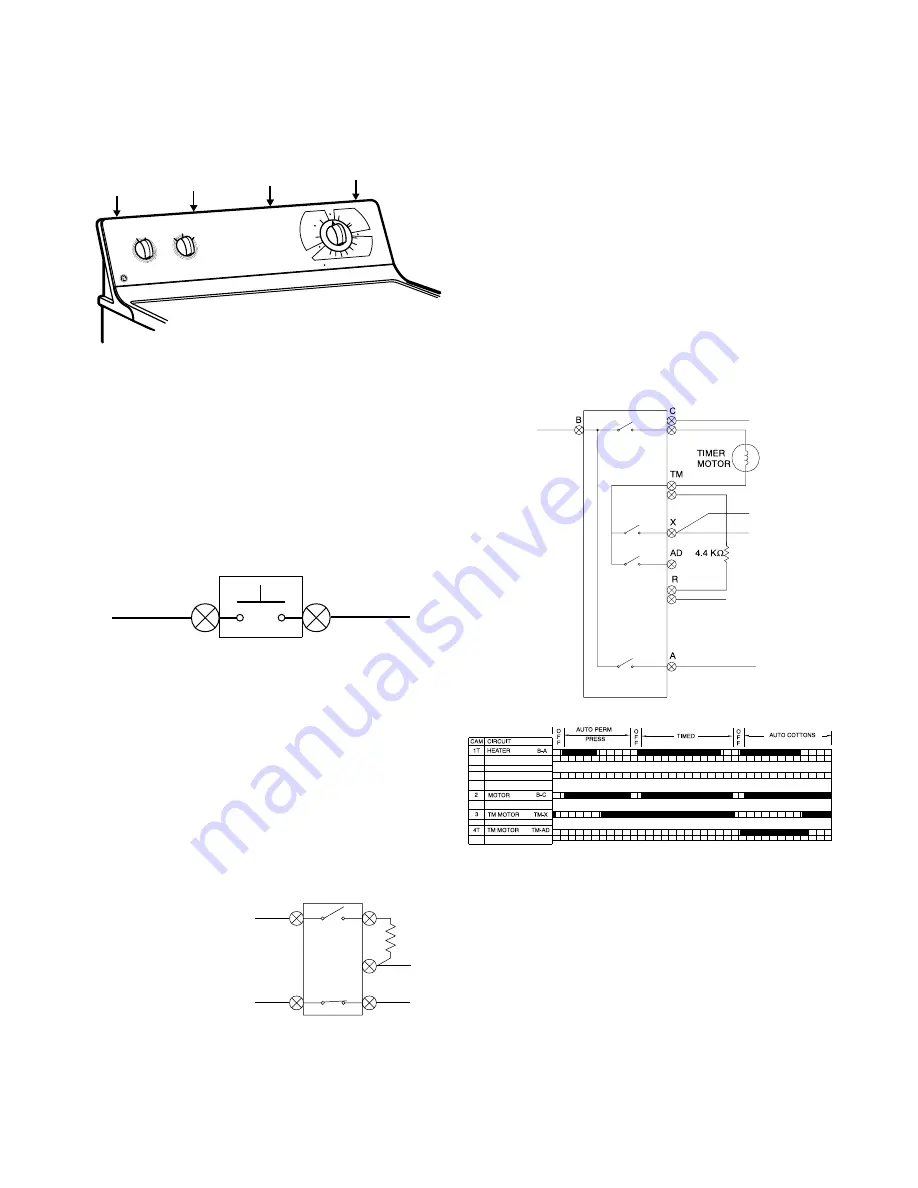

Dryer Controls

To access the dryer controls, disconnect power and

remove the four Phillips screws at the top of the

switch trim. Grasp the trim at the top and pull forward.

Three tabs at the bottom fit into slots on the top panel.

START

HIGH

MEDIUM

FLUFF

MORE DRY

MORE DRY

= PREFERRED REGU

LAR SETTING

80 MIN

70

60

50

40

30

20

LESS DRY

LESS DRY

COOL

DOWN

AUTOMATIC

COTTONS

AUTOMATIC

PERMANEN

T

PRESS

TIMED DRY

3 Cycle Automatic

Heavy Duty La

rge Capacity

START

TEMPERATU

RE

Start Switch

The start switch energizes the start windings on the

drive motor. It is a momentary contact, rotary switch.

To test the switch, remove the wires and check for

continuity between the switch terminals. There

should be continuity only while turning the switch

clockwise. Once released, the terminals should read

open. Should the switch need to be replaced, turn

the switch clockwise (as viewed from the back) to

release it from the switch trim.

Timer

The timer is an electromechanical control with a 120v

drive motor. Depending upon the model, the timer

will control cycles for timed fluff (no heat), timed dry,

automatic cottons and/or automatic permanent

press. On a timed cycle, the timer motor receives

120 volts continuously for the number of minutes

selected for the cycle. When an automatic cycle is

chosen, the time will vary based of the quantity of

clothes and their moisture content. When the heat

source is on, the timer motor does not receive power.

When the clothes warm and the control thermostat

is satisfied, the heat is turned off and voltage is then

supplied to the timer motor. When the thermostat

cools, the heat is again turned on and the timer stops.

As the clothes dry, the control thermostat reaches

temperature faster and the timer motor receives

power more often until the end of cycle is reached.

To diagnose the timer, use the timer bar chart located

on the mini manual behind the switch trim. Rotate

the timer to a point in the particular cycle you want

to check. Find the appropriate location the timer

pointer is set in the cycles across the first column.

Read vertically down the chart from that point. At

each point you cross a shaded row, the contacts

listed at the left on the same row should have

continuity. Note the shaded areas are proportional

to the total time, so take several continuity

measurements at different points within the cycle

before determining the timer needs replacement.

Timer Bar Chart

Summary of Contents for DBL333

Page 17: ...15 DBL333E ...

Page 18: ...16 DBL333G ...

Page 19: ...17 DCL333E ...

Page 20: ...18 DCL333G ...

Page 21: ...19 DVL223E ...

Page 22: ...20 DVL223G ...

Page 28: ...26 Model DBL333EY0WW shown ...

Page 30: ...28 Model DBL333EY0WW shown ...

Page 32: ...30 Model DBL333EY0WW shown ...

Page 34: ...32 Model DBL333EY0WW shown ...

Page 36: ...34 Model DBL333GY0AAshown ...