24

R E LI AG E A R® S B

S W I TC H B OA R DS

—

44

—

45

Testing and inspection

DANGER

WARNING

CAUTION

NOTICE

SAFETY

INSTRUCTIONS

Warning:

Keep equipment de-energized during

cleaning and inspection. Failure to do so may

result in serious injury or death.

After the equipment has been installed and

all connections made, test and inspect the

switchboard before energizing. Although the

equipment and devices have been inspected at the

factory, perform a final field test to be certain that

the equipment has been properly installed and that

all connections are correct and have not loosened

during transportation. Check all terminals,

connections, and hardware for correct torque

values. Check all Kirk key interlocking schemes

to ensure desired performance. Make sure the

incoming line is de-energized while all tests are

in progress.

In addition to these mechanical checks, use a

megohmmeter to test the switchboard. Open all

switchoard devices, remove all instrumentation

and control fuses, and isolate the neutral from

ground. All scraps of wire, plaster, dust, and other

foreign material must be removed. Vacuuming is

recommended. Use a megohmmeter developing

500 volts. Conduct electrical insulation resistance

tests from phase to phase, phase to ground, phase

to neutral, and neutral to ground. If any

switchboard tested under the above conditions

shows resistance values less than 1 megohm,

inspect it for possible tracking on insulation or

insulation breakdown. For additional details

consult* ANSI/NEMA PB 2.1.

—

45

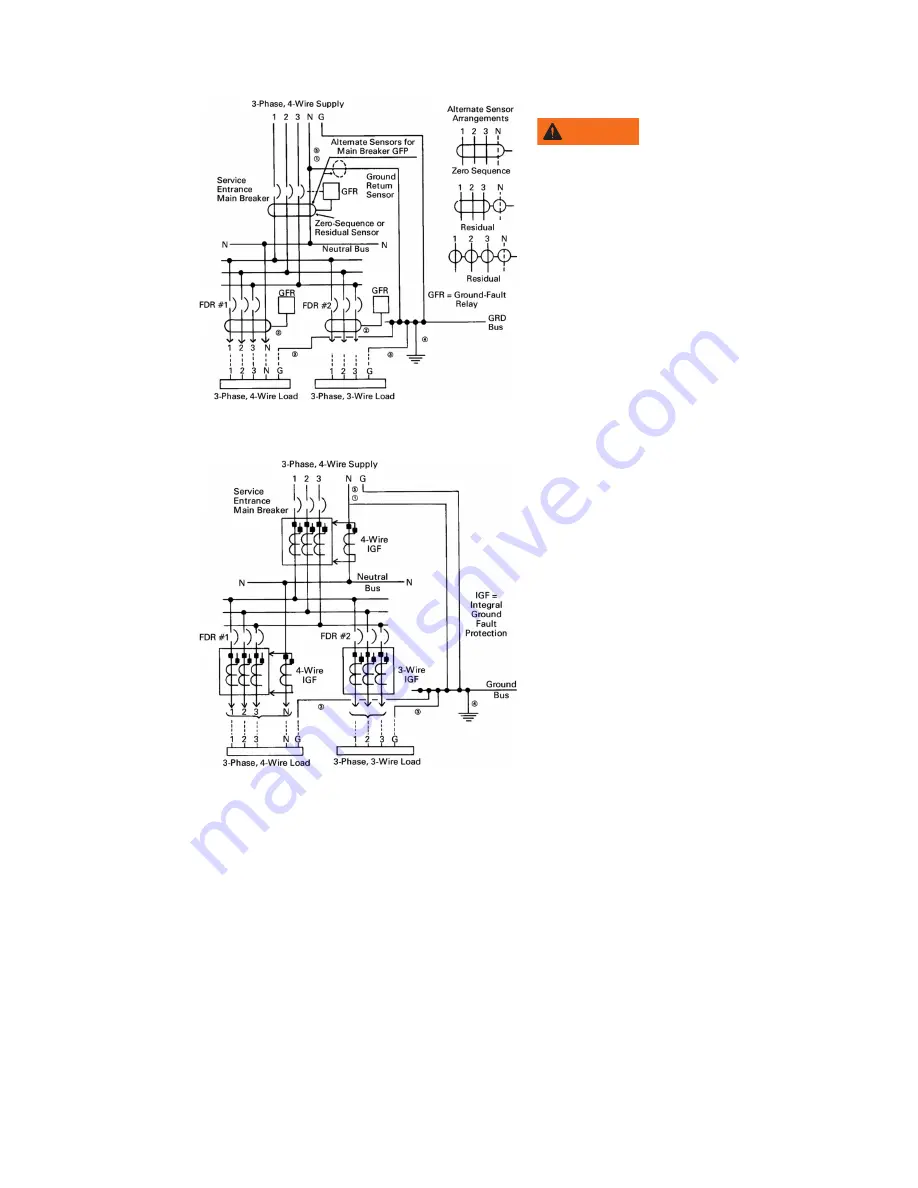

Typical single-source

ground-fault protection

using integral

ground-fault trips.

—

44

Typical single-source

ground-fault protection

using ground-fault relays

Summary of Contents for ABB ReliaGear SB

Page 1: ...INSTALLATION OPER ATIONS AND MAINTENANCE MANUAL ReliaGear SB Switchboards ...

Page 2: ......

Page 30: ...30 RELIAGEAR SB SWITCHBOARDS ...

Page 31: ......