39

Wireless Monitor operation

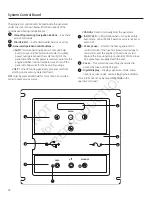

1. Remove battery access cover (A) on back of monitor

and install 2 AA batteries. (Observe correct battery

polarity which is embossed in the bottom of the

battery compartment). Replace battery access cover.

2. The wireless monitor does not have an on/off

switch. When batteries are installed correctly,

the GENERATOR READY green LED light will flash

once every 7 seconds indicating the status of the

generator.

NOTICE

If communication does not begin upon placing the

generator in AUTO, installing batteries, and pressing System

Update, the monitor may need to be re-linked. To link, follow

Steps 3 through 6.

3. Locate the MENU AND ESCAPE buttons on the control

panel (B) . Press and hold for 3 seconds to enter the

linking mode.

4. “LINKING MODE” will scroll across the generator

control panel.

5. Locate and hold the SYSTEM UPDATE button (C) on

the wireless monitor for 5 seconds. All 3 LEDs will flash

until the monitor links to the generator. Once it links,

the monitor will display the current state. The monitor

will try to link for 1 minute. (This step can only be

completed when the generator is in Linking Mode).

6. Once the link has been confirmed, press the OK

button on the generator control panel to exit or the

control board will turn off linking after 5 minutes. The

generator will now communicate with the wireless

monitor.

NOTICE

It may take up to 1 minute for the monitor to begin

displaying the generator status correctly.

DEALER

NAME

DEALER

PHONE

generator power

service needed

generator ready

system update

1 low battery voltage

2 low fluid level

3 under/over voltage

4 engine does not start

part #: 316196 fcc id: MCQ-XBS2C IC id: 1846A-XBS2C

5 low frequency

6 engine overspeed

7 high temperature

8 transfer switch

# of flashes service needed

a

ok

menu

esc

auto

off

manual

B

B

DEALER

NAME

DEALER

PHONE

generator power

service needed

generator ready

system update

1 low battery voltage

2 low fluid level

3 under/over voltage

4 engine does not start

part #: 316196 fcc id: MCQ-XBS2C IC id: 1846A-XBS2C

5 low frequency

6 engine overspeed

7 high temperature

8 transfer switch

# of flashes service needed

c

a

B

c

NOTICE

The wireless monitor was linked to the generator at

the factory. Communication will begin upon the installation

of the batteries and the generator being placed in AUTO

mode. You may need to press System Update one time.

NOT

for

REPRODUCTION

Summary of Contents for 20 kW Home

Page 10: ...10 Intentionally Left Blank N O T f o r R E P R O D U C T I O N ...

Page 41: ...41 NOTES N O T f o r R E P R O D U C T I O N ...

Page 42: ...42 NOTES N O T f o r R E P R O D U C T I O N ...

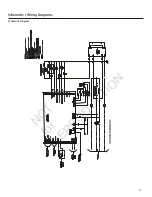

Page 43: ...43 Schematic Diagram Schematic Wiring Diagrams N O T f o r R E P R O D U C T I O N ...