Masoneilan Model 4411 Electropneumatic Transducer Instruction Manual | 3

© 2015 General Electric Company. All rights reserved.

To meet the EMC specifications, screened cable should be used

for installation� The cable screen should be connected to the

internal earth bonding point of the I/P� An earth strap should

also be connected from the external earth bonding point of

the I/P to a common earth point� The cable screen should

not

be connected at the signal source when used in Intrinsically

Safe (IS) environments� The I/P has been thoroughly tested in

accordance with:

Electromagnetic compatibility (EMC)

Generic Standards – Immunity for industrial environments

Electromagnetic compatibility (EMC)

Generic Emissions Standard – Industrial environment

Please consult wiring diagram for further information� The

results obtained from these tests show that with the screen

arrangement shown in the installation diagram, the typical

sustained output pressure shift is <+/-5% full scale� Consult

supplier for further details�

Instrument Mounting

The converter can be mounted directly onto a valve, onto any

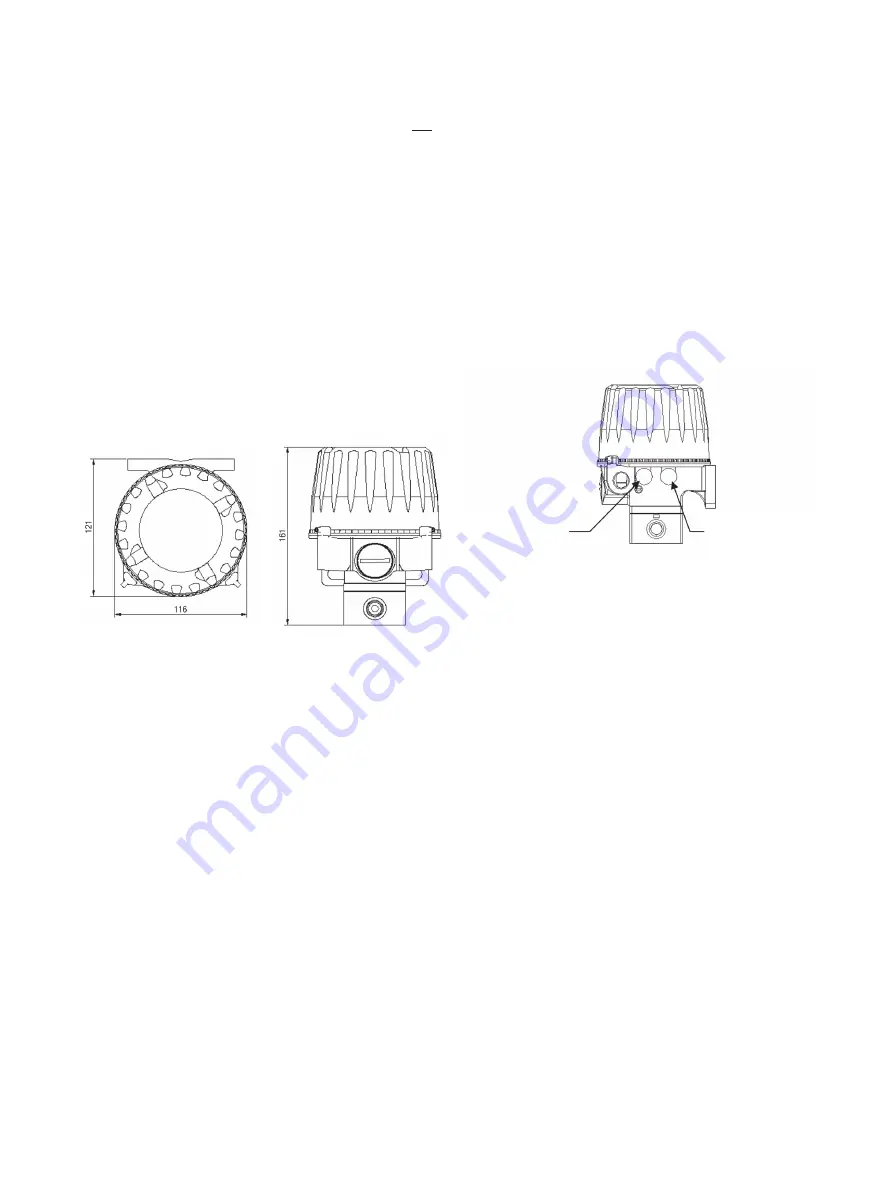

suitable flat surface, or onto 2” (50mm) pipe� Dimensional details:

Figure 2

These converters will operate in any position, with slight

re-calibration adjustments, normal operation is in the upright

position, i�e� with the screwed lid horizontal� The unit is weather

resistant when the lid is removed for connection or calibration,

but should not be left uncovered during operation or for

extended periods of time� They are unaffected by shock and

vibration, but severe vibration environments are best avoided�

The instruments are protected against environmental effects,

to a level of Type 4X (IP66)� Sensible positioning should be used

if the local environment is severe�

Temperature compensation is designed into these converters

which will operate over a range from –40° to +85°C (-40° to

+185°F)� Maximum life is obtained if extreme temperature cycling

is avoided� In extreme direct sunlight, sun-shading is advised�

The pneumatic exhaust and the bleed are routed through the

baffles� The baffles must not be blocked with paint and/or

plastic sheeting etc�

Captured Bleed Version

The baffles and the baffle cover are fitted to maintain the

adequate Ingress Protection (IP) rating of the instrument�

Removal of these protective parts will invalidate the IP and the

NEMA 4X rating of the instrument�

For captured bleed installation, remove the baffle cover and

unscrew both the baffles, fit 1/8" NPT fittings to two separate

lengths of pipes, to exhaust and bleed gas to a safe area

installation�

Vented gas from the enclosure through bleed port must not

be re-circulated and introduced back into the process stream�

Exhaust port installation must not have any restriction to

create backpressure to cause instrument to malfunction�

Instrument installation for captured bleed version must be

under the installer’s discretion�

Note: Exhaust Port is nearer the conduit entry (LH side)

Enclosure Bleed Port is on the RH side. (See Figure 3.)

Figure 3

Pneumatic Installation

These instruments are recommended for use with clean, dry,

oil free instrument grade air to BS�6739:1986 or ANSI/ASA-57�3

1975 (R1981)�

Dew Point:

At least 10°C (18°F) below (-40°C) minimum

anticipated ambient temperature�

Dust:

Filtered to below 50 microns�

Oil Content:

Not to exceed 1ppm mass�

The instrument is factory calibrated with a supply pressure of 30

psig (2 bar) ±10%� Operation is possible at any pressure between

18 and 150 psig (1�3 to 10 bar), though recalibration may be

necessary towards these limits to maintain specified accuracy�

The inlet and outlet ports are threaded 1/4" NPT female and

suitable fittings should be used� For most installations 1/4"

(6mm) pipe will be adequate� If a large actuator, high flow

rates or long pipework is necessary then a larger diameter

should be used�

Plastic tubing, e�g� Nylon is preferable where circumstances

permit, since it is normally very clean internally� In all cases,

purge the supply pipework before connection to the converter�

Two gauge ports are provided to facilitate direct mounting of

a pressure gauge� To use one of these ports remove the plug

(using a 1/4" or 3/16" Hexagon Key) in a de-pressurized state,

and connect the gauge� The ports are threaded 1/4" NPT at

the back of the unit and 1/8" NPT at the front�

Exhaust Port

Enclosure Bleed Port