Page 7-1

ProCut 20P – Installation and Operating Instructions

7. o

Perator

M

aIntenance

c

arInG

For

the

P

ro

c

ut

20P

The only maintenance required by the operator is to

perform what is described in this section. Perform

only

the routine maintenance procedures referred to

in these instructions.

WARNINGS:

•

Before performing maintenance on the machine,

turn the Circuit Breaker and Switch to OFF.*

•

Do not attempt to repair the machine. Refer

service to qualified service personnel.

•

Do not lift, tilt, or attempt to move the machine.

You can be severely injured or crushed.

Failure to observe these warnings could result in

severe personal injury or death.

*If rotating or replacing the Cut Stick, see the

instructions, shown below, before turning the

machine OFF.

CAUTIONS:

• Do not place materials on the table or near the

Cutting Blade other than paper.

• Do not cut through metal objects such as paper

clips or staples.

•

Do not allow foreign objects to fall into the working

area of the machine.

Failure to observe these cautions could result in

damage to the machine.

c

leanInG

t

he

P

aPer

c

utter

At the end of the day or project, clean up all waste

and extra scraps off the working table.

c

ut

s

tIck

r

otatIon

and

r

ePlaceMent

The Cut Stick provides a clean cut as the Cutting

Blade makes contact with it. When the Cut Stick is

badly abraded and the paper is not cut cleanly, either

rotate or replace the Cut Stick. The Cut Stick can be

rotated to provide eight cutting surfaces.

1. Turn the Circuit Breaker and Switch to

OFF

.

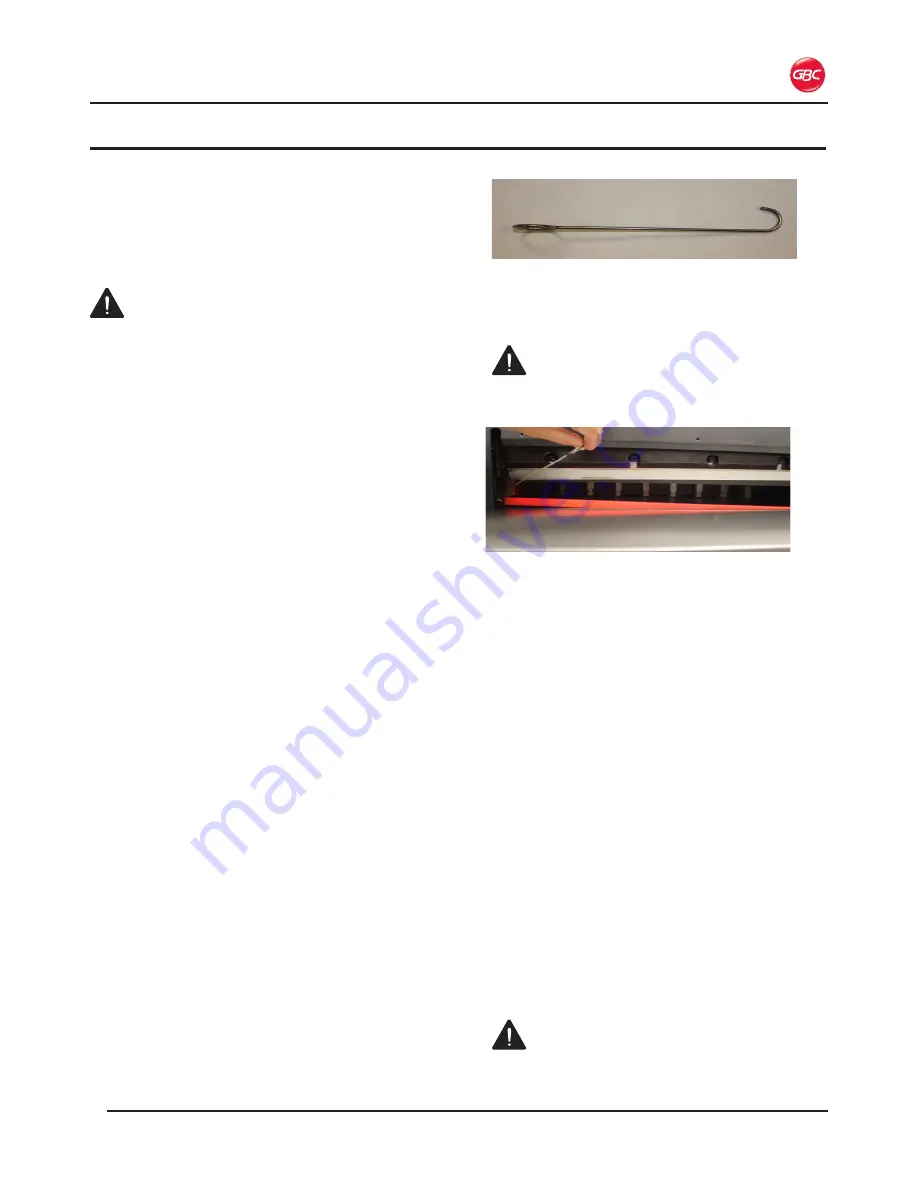

2.

Insert the Stick Removal Tool into the end of the

Cut Stick and pull up.

Figure 19. Cut Stick Removal Tool

3.

From the front of the machine, lift the Cut Stick

out of the groove.

WARNING:

Keep fingers and hands clear of

the Cutting Blade. Failure to observe these

warnings could result in severe personal injury.

Figure 20. Cut Stick Removal

4.

Do one of the following:

• Rotate the Cut Stick

• Turn the Cut Stick end-to-end

•

Replace the Cut Stick if all eight surfaces

are abraded.

5.

Put the Cut Stick back into the groove of the

machine, making sure that both ends are level

with the Working Table.

6. With the machine powered ON, press the

Reset

button.

• The Cutting Blade and Clamp move to home

position.

B

lade

r

ePlaceMent

The Cutting Blade can be sharpened for re-use

or replacement. The blade should be sharpened

professionally. It will need to be sharpened or

replaced under any of the following conditions.

• Media is cut poorly

• Cutting sounds abnormal

•

After approximately 2,000 cuts

CALL YOUR LOCAL SERVICE TECH OR DEALER

FOR BLADE REMOVAL OR SHARPENING.

WARNING: Do not attempt to service the

Cutting Blade. Failure to observe these warnings

could result in severe personal injury.