SERVICE MANUAL

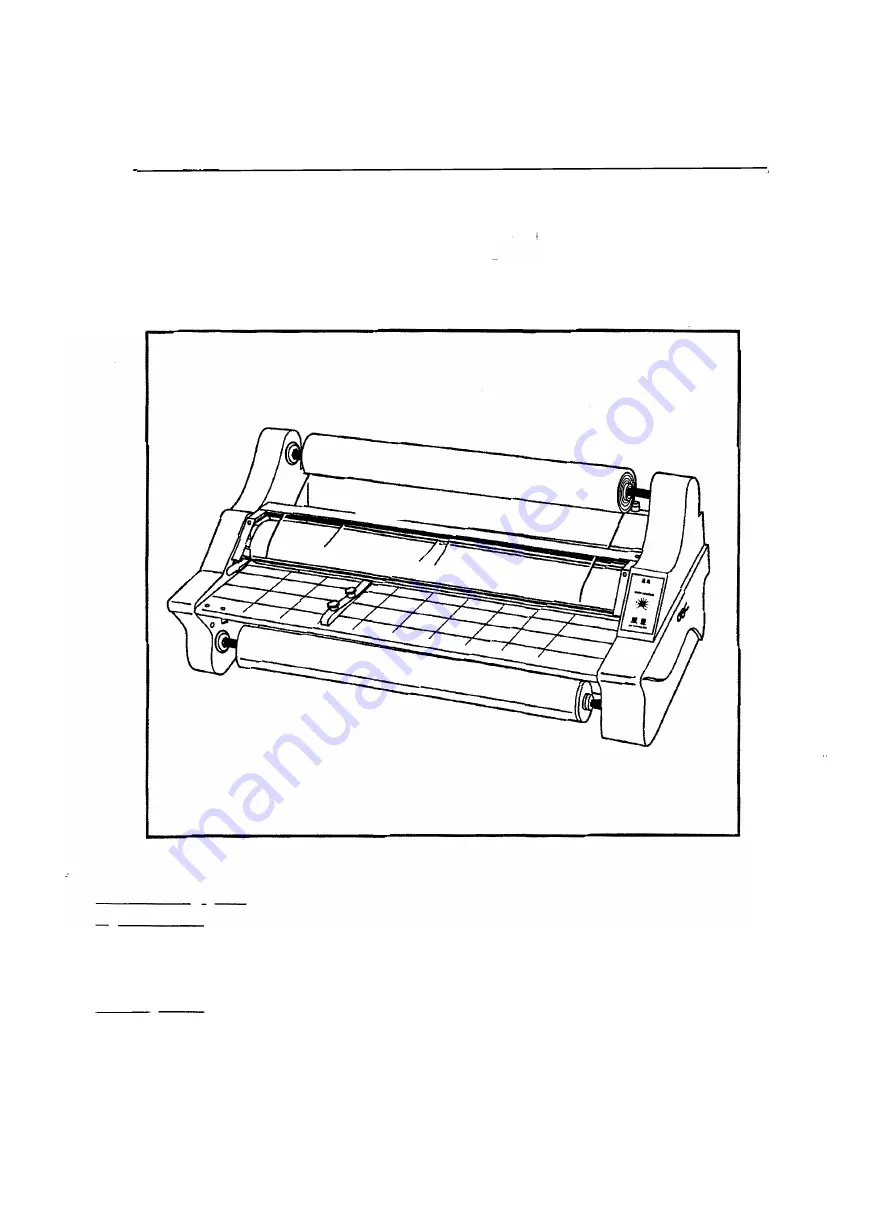

Ci8CDOC� 2700

---== ----

Final Assemhll'.. No.

Service Manual PIN 6001112

DQcuseal 2700

115V

1710801

Australia

1710831

Europe

1710811

Swiss

1710841

UK

1710821

Japan

1710851

Docuseal 3100

115V

1710861

Australia

1710891

Europe

1710871

Swiss

1710901

UK

1710881

Japan

1710911