2-17

Chapter 2 - Principles of Operation

Wash System - Cont.

Ventilator Section Wash Groups - cont.

Heavy Duty equipment would wash at a different frequency than a Ventilator covering Light/Medium Duty

equipment, as shown in the example Table T-2-16-1. The length of each Wash Cycle, for each Ventilator

section, is programmed in the Command Center. If two or more Ventilator sections have the same cooking

equipment Duty, at the conclusion of the Wash Cycle for Ventilator section # 1, either an Extractor Wash or

Plenum Wash, the Wash Cycle for Ventilator section #2 would immediately begin or it can be delayed by

programming the Command Center. The delay can be programmed for up to 99 minutes. Refer to the Op-

eration and Maintenance Manual for the Gaylord Command Center for complete programming instructions.

Table T-2-17-1

Recommended Detergent

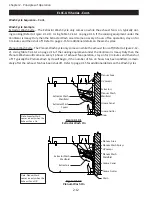

FORMULA G-510EF is the only cleaner recommended by Gaylord

Industries for use in the wash down system of The Gaylord Ventila

-

tor. FORMULA G-510EF is a concentrated colloid cleaner specially

formulated to remove the daily accumulation of grease inside the

Ventilator without damaging the rubber and synthetic parts of the

solenoid valves and the detergent pumping system. FORMULA

G-510EF is safe for kitchen personnel and has a variety of uses.

FORMULA G-510EF Safety

FORMULA G-510EF is registered with the U.S. EPA’s Design for the Environment Program (DfE) which seeks

to promote the use of institutional cleaners and maintenance products with improved environmental and

human health characteristics.

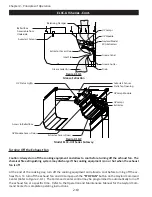

FORMULA G-510EF for the Ventilator Wash System

Pour FORMULA G-510EF directly into the detergent tank located inside the Wash Control Cabinet (Refer to

Figure 2-11-2). The detergent pump injects the detergent into the Main Feed Line where it dilutes with the

hot water at the proper ratio (Refer to Figure 2-11-2).

FORMULA G-510EF for Cleaning the Ventilator Exterior

Mix one part FORMULA G-510EF to twenty parts water in hand spray bottle. Spray on, let stand for a few

minutes and wipe off.

FORMULA G-510EF for Other Cleaning Jobs

The colloidal action of FORMULA G-510EF makes it a cleaner especially well-suited for use in kitchens.

The colloids break up dirt and grease into millions of tiny particles that constantly repel each other. These

particles cannot recombine or redeposit on a surface and are, therefore, easily washed away. FORMULA

G-510EF contains no harsh chemicals, yet offers outstanding performance on the toughest cleaning jobs.

@40 PSI *

@80 PSI *

Extractor Wash

0.51

0.72

Plenum Wash

0.45

0.63

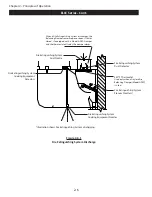

Hot Water Requirments

Water Temperature: 140

º

F Min. to 180 °F Max.

Flow Pressure: 40 PSI Min. - 80 PSI Max. at the Wash

Control Cabinet while in a Wash Cycle

GPM Per Lineal Ft. of Ventilator

Water Consumption Table

Type of Wash

* All Pressures Measured at the Wash Control Cabinet with

no more than 30 ft. of 1" pipe line between the Ventilator

and Wash Control Cabinet

Summary of Contents for ELXC Series

Page 40: ...4 6 INTENTIONALLY LEFT BLANK ...

Page 74: ...7 1 Chapter 7 Wiring Diagrams ELXC GBD with AUTOSTART ...

Page 75: ...7 2 Chapter 7 Wiring Diagrams ELXC GFBD with AUTOSTART ...

Page 76: ...7 3 Chapter 7 Wiring Diagrams ELXC GBD UVi with AUTOSTART ...

Page 77: ...7 4 Chapter 7 Wiring Diagrams ELXC GFBD UVi with AUTOSTART ...

Page 83: ...A 6 INTENTIONALLY LEFT BLANK ...