3

www.gastrofrit.ch

© Switzerland Gastrofrit AG

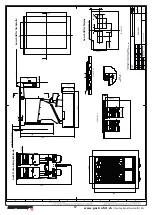

Models and variants

ELM-300 built in

Item No. 101135

ELM-400 built in

Item No. 101145

ELM2-400built in Item No. 101146

ELM2-500 built in Item No. 101251

F-300 built in

Item No. 100130

F-400 built in

Item No. 101145

F2-400 built in

Item No. 102240

F2-500 built in

Item No. 100251

TW-350 built in

Item No. 110135

TW-400 built in

Item No. 110140

Power connection / technology

Please note that the power fluctuations, safeguards

and frequency ranges 50 Hertz or 60 Hertz differ in

individual countries. Before commissioning, check

the exact requirements for carefree operation of the

device.

The electricity connection may only be provided by

trained qualified personnel can be connected. Accor-

ding to the requirements stipulated in the country.

• After switching on the main switch, the device

starts and lights up in the ON / OFF LED.

• The 3x400V (3L + N + PE) power connection is

made with a standard-compliant CE plug.

Electricity

Danger: Use silicone braids for the main connection of

the devices. To guarantee trouble-free operation:

• The specifications regarding cable cross-section

and fuse protection must be strictly observed.

No other devices or power consumers may be

connected to the fuse protection of the sup-

ply line. The devices were tested for their EMC

compatibility. The test reports can be viewed at

Gastroifrit.

• You need to make sure that no cables or conduits

are pinched.

Design of the area around the collection container:

The base for the collecting container should consist

of low-wear, easy-to-clean material. It is important to

ensure that the container can be removed quickly for

easy cleaning. The container should also be guided to

the side and have a defined end position.

1. Protection against accidental contact must be pro-

vided during installation.

2. The devices must not be built into flammable

material.

3. If the device is installed next to a large heat

source, sufficient ventilation of the control box

must be ensured. (maximum temperature of the

control box 70 ° C)

4. Wird das Gerät neben einer großen Hitzequelle

eingebaut, ist auf eine genügende Lüftung des

Steuerkastens zu achten. (maximale Temperatur

des Steuerkastens 70°C)

Installation of the heating basin (normal case)

Inlay and silicone seal

The heating basin is placed in the corresponding ope-

ning, the joint must be sealed with silicone. The holes

provided for frame assembly can be closed with blind

rivets or screws. The silicone joint must be checked re-

gularly for leaks in order to avoid the ingress of liquids

in the long term.

Installation of heating basin (additional parts)

With frame parts or upstand kitchen cover The

heating basin can also be attached to the table with

frame parts. The frame parts should be around 20mm

shorter than the outside dimensions of the pool. When

installing in a metal cover, this can also be folded up

analogously to the frame part. The frame parts are

not part of the Gastrofrit delivery. For the installation

of the frame parts, the opening must be 2mm larger.

The joint still has to be sealed with silicone. The frame

parts are bent from 1.5mm stainless sheet metal and

screwed to the table and basin.

Assembly instructions lift motor

Please make sure that you have connected the power

plug correctly if it was not installed by Gastrofrit AG.

The earth (color: yellow / green, symbol 0) and the

neutral wire (color blue, symbol N) are marked in the

connector housing, connect the phases so that the

brown wire is in the middle of the two black wires.

Electrical connection of the lifting motor

The connection cable contains the following 4

strands:

• yellow/green ground wire

• blue

neutral conductor

• brown

Phase lift motor up

• black

Phase lift motor down

When you are standing in front of the device and have

tilted the cover towards you, you can connect the

strands as follows:

Please connect the earth to the metallic (gold-colored)

earth connection. The neutral conductor to the blue

clamp, the brown phase to the left gray clamp, the