2

CONTENTS

Section

Page

General Information

2-4

Operating & Lighting Procedure

5-8

Care & Maintenance

9-10

Parts List & Hardware List

11-12

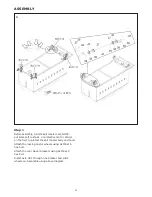

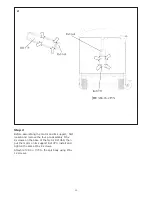

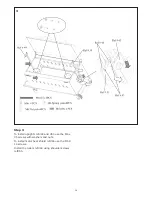

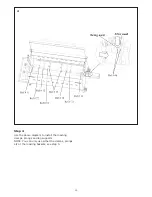

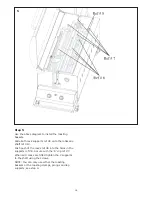

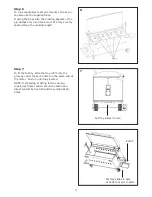

Assembly Instructions

13-19

Safe Appliance Locations

20

GENERAL INFORMATION

Gas Installation Codes

• Spit roaster must be used in accordance with

New Zealand Standard 5261 “Gas Installations”.

• Spit roaster for use with bottled gas are

labelled ‘LPG’.

• Spit roaster for use with natural gas are

labelled ‘natural gas’ and must be installed

by an authorised person. Check the gas type

sticker attached to the spit roaster.

Clearances

Minimum Clearances from combustible materials

must be:

Rear - 600mm Sides - 600mm Above - 600mm

Hose & Regulator Safety

The regulator and hose assembly supplied with the

spit roaster are suitable for LPG only. A gas

regulator adjusted to have an outlet pressure of

2.75kPA is supplied for connection to the LPG

cylinder. The gas regulator and hose assembly

supplied with the spit roaster must be used.

Replacement gas regulators and hose assemblies

must be those

specified

by the spit roaster

manufacturer.

When connecting the hose and regulator assembly

to the gas cylinder, take care to avoid unnecessary

twisting of the

flexible

hose.

After the assembly has been secured, turn on the

gas and check for leaks by brushing a soap and

water solution over all connections.

If you are unable to correct the leak by tightening

the connections, turn off the gas and contact the

supplier immediately.

Always ensure the spit roaster is kept away from

flammable

materials and the gas cylinder clear of

any heat source.

When changing over from an empty gas cylinder

to a full one make sure this procedure is carried

out in a

flame

free atmosphere.

Specifications

Spit roaster

specifications

can be found on the

data label attached to the spit roaster body.

Hose connection thread at gas inlet is 1/4” BSPT.

Summary of Contents for GSB300

Page 10: ...10 EXPLODED DIAGRAM ...