A

A

90

Excessive Drive Train Noise

•

Chain loose. Adjust tension with take-up assembly; remove link from chain if take-up does

not provide enough adjustment

•

Gears worn in motor gearhead (refer to manufacturer’s instructions).

•

Defective idler bearing on chain wrap.

•

Defective shaft bearing.

•

NOTE:

Gearhead motors are normally somewhat noisy. If motor is quiet when slitting

material, the motor is probably ok.

Lubricating & Maintenance Instructions

To maintain the Gary Machinery Slitter in its best operating condition and to avoid downtime, the

following items should be checked on a regular schedule.

1. The gear reducer should be checked when received to be sure the oil is at the proper level.

It should then be checked at regular intervals, with visual inspection of oil seals for possible

leaks. If oil is required, Browning GL32HT (or equivalent) is recommended. The oil can be

added through the plug at the top of the reducer. Caution must be taken not to overfill the

unit.

2. The arbors, knives, gauge bar, guide rods and skid table should be wiped down and

lubricated with a light oil such as WD-40. This will help prevent rust and remove debris from

the slitter. They should be re-lubricated on a regular basis. This re-lube period should be

more often if the slitter is operated in extremely dusty atmospheres.

3. The guard on the drive side of the slitter incorporates the main arbor bearings and provides

access to the chain and gears. Use a heavy-duty chain lube to lubricate chain and gears

before replacing the guard. Aerosol form is most convenient and effective. Keep drive

chain clean and well lubricated and check chain tension regularly.

4. Keep all fasteners tight and check that all guards are in place.

5. Lightly lubricate gauge rods periodically to maintain smooth movement as well as keep

clean.

6. Keep all unpainted surfaces lightly oiled to prevent rust.

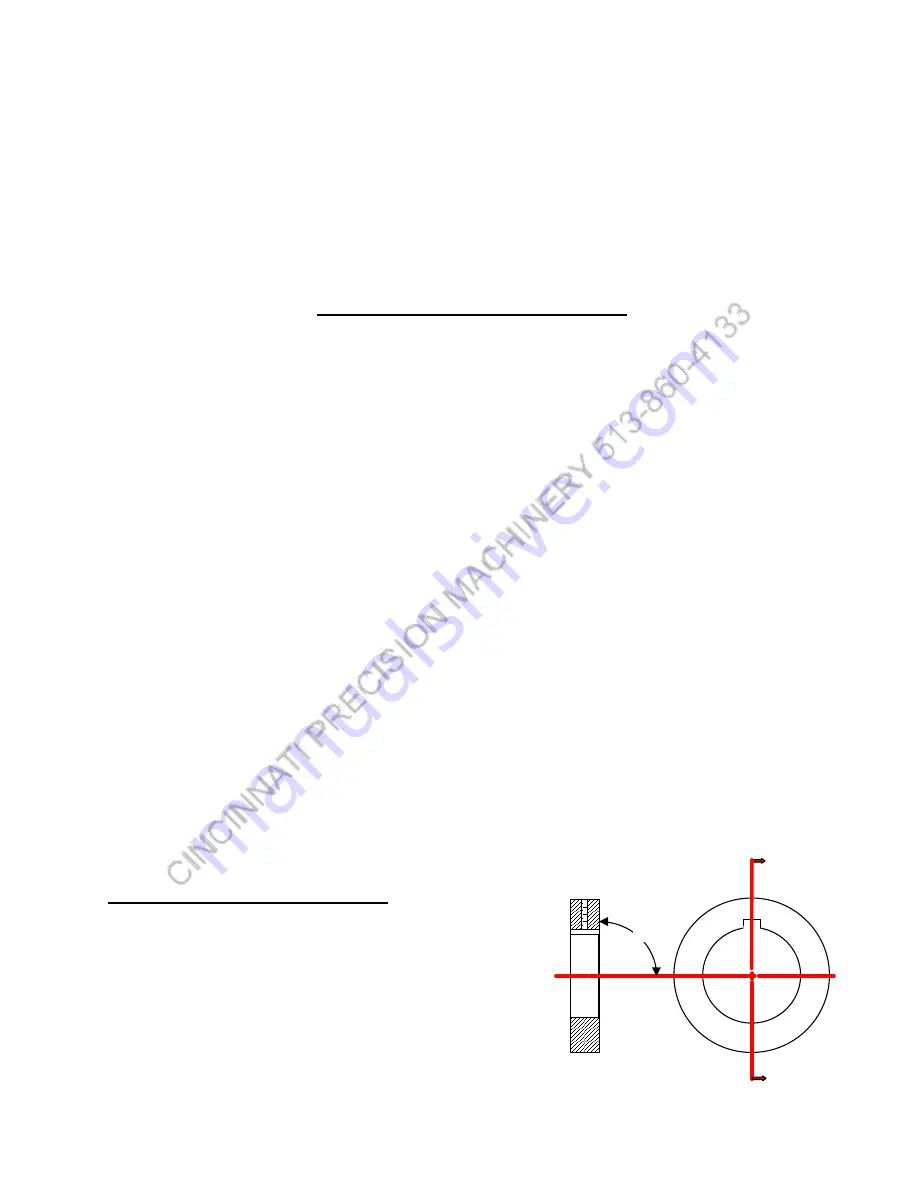

Slitter Knife Sharpening Procedure:

1. The knife sharpening must be done by grinding the side

faces.

DO NOT GRIND OUTSIDE DIAMETER

.

2. Squareness of bore to side face must be maintained

(90°)