GHP 12 Installation Instructions

11

4. With the cables hanging straight down, connect the arm with the

thumbscrew.

The cables must hang straight down for the CCU to accurately read

your heading.

5. Hand-tighten the thumbscrew until the CCU is held firmly in the

bracket.

Do not overtighten the thumbscrew.

Connecting the CCu

1. Route the connector-terminated end of the CCU/ECU interconnect

cable to the ECU and make the connection.

2. Route the wires from the bare-wire portion of the cable to the CCU/

ECU interconnect cable.

• Route the red and blue wires to the location where you plan to

install the alarm (

).

If the cable is not long enough, extend the appropriate wires with

28 AWG (.08 mm

2

) wire.

• Route the yellow wire to the location where you plan to install

the GHC 10 (

If the cable is not long enough, extend the yellow wire with 22

AWG (.33 mm

2

) wire.

3. Cut and tape the remaining bare wires; they are not used.

alarm Installation

The alarm audibly alerts you to important GHP 12 events. It must be

installed near the helm station.

Mounting the alarm

Before you can mount the alarm, you must select a mounting location

Secure the alarm with cable ties or other appropriate mounting

hardware (not included).

Connecting the alarm

1. Route the alarm-cable to the bare-wire end of the CCU/ECU

interconnect cable.

If the cable is not long enough, extend the appropriate wires with 28

AWG (.08 mm

2

) wire.

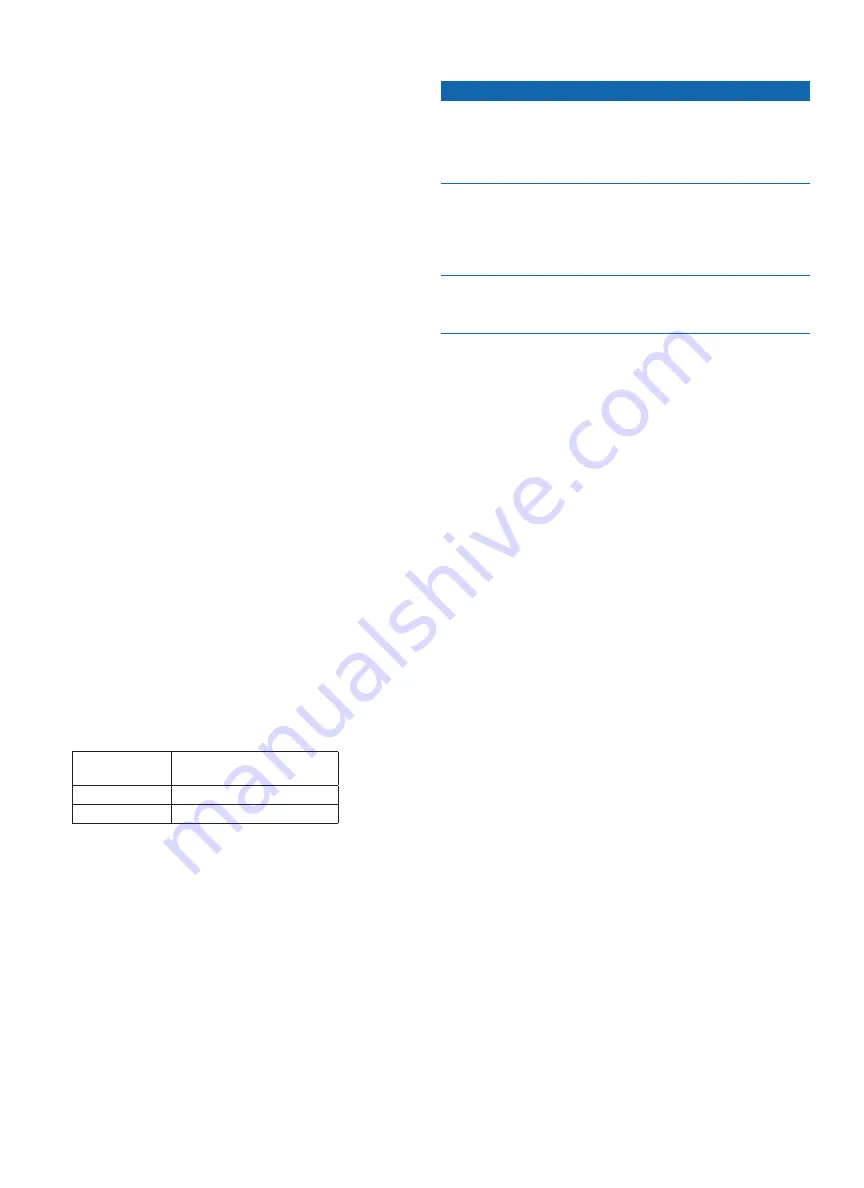

2. Connect the cables, based on the table below.

alarm Wire

Color

CCu/ECu Interconnect Cable

Wire Color

White (+)

Red (+)

Black (-)

Blue (-)

3. Solder and cover all bare-wire connections.

GHC 10 Installation

Install the GHC 10 by flush-mounting it in the dashboard near the helm,

connecting it to the yellow wire from the CCU/ECU interconnect cable,

and connecting it to a NMEA 2000 network.

To use advanced features of the GHP 12, optional NMEA

2000-compatible or NMEA 0183-compatible devices, such as a wind

sensor, a water-speed sensor, or a GPS device, can be connected to

the NMEA 2000 network or connected to the GHC 10 through NMEA

0183.

Mounting the GHC 10

Notice

The temperature range for the GHC 10 is from 5°F to 158°F (from

-15°C to 70°C). Extended exposure to temperatures outside of this

range (in storage or operating conditions) may cause failure of the

LCD screen or other components. This type of failure and related

consequences are not covered by the manufacturer’s limited warranty.

If you are mounting the GHC 10 in fiberglass, when drilling the

four pilot holes, it is recommended to use a countersink bit to drill a

clearance counterbore through only the top gel-coat layer. This will

help to avoid any cracking in the gel-coat layer when the screws are

tightened.

Stainless-steel screws may bind when screwed into fiberglass and

overtightened. Garmin recommends applying an anti-galling, stainless

anti-seize lubricant to the screws before installing them.

Before you can mount the GHC 10, you must select a mounting location

1. Trim the flush-mount template and ensure it will fit in the location

where you plan to mount the GHC 10.

The flush-mount template is included in the product box, not in

these instructions.

The flush-mount template has adhesive on the back.

2. Remove the protective liner from the adhesive on the back of the

template and apply it to the location where you plan to mount the

GHC 10.

3. If you will be cutting the hole with a jigsaw instead of a 3.5

in. (90

mm) hole saw, use a

3

/

8

in. (10 mm) drill bit to drill a pilot hole as

indicated on the template to begin cutting the mounting surface.

4. Using the jigsaw or the 3.5

in. (90 mm) hole saw, cut the mounting

surface along the inside of the dashed line indicated on the flush-

mount template.

5. If necessary, use a file and sandpaper to refine the size of the hole.

6. Place the GHC 10 into the cutout to confirm that the four mounting

holes are correct.

7. Select an option:

• If the mounting holes are correct, proceed to step 8.

• If the mounting holes are not correct, mark the correct locations

of the four mounting holes.

8. Remove the GHC 10 from the cutout.

9. Drill the four

1

/

8

in. (3.2 mm) pilot holes.

If you are mounting the GHC 10 in fiberglass, use a countersink bit

as advised in the notice.

10. Remove the remainder of the template.

11. Place the GHC 10 into the cutout.

12. Securely fasten the GHC 10 to the mounting surface using the

supplied screws.

If you are mounting the GHC 10 in fiberglass, use a anti-galling

lubricant as advised in the notice.