PART 1: Game Gear Recap & Functionality Test

STEP 2

Page 5

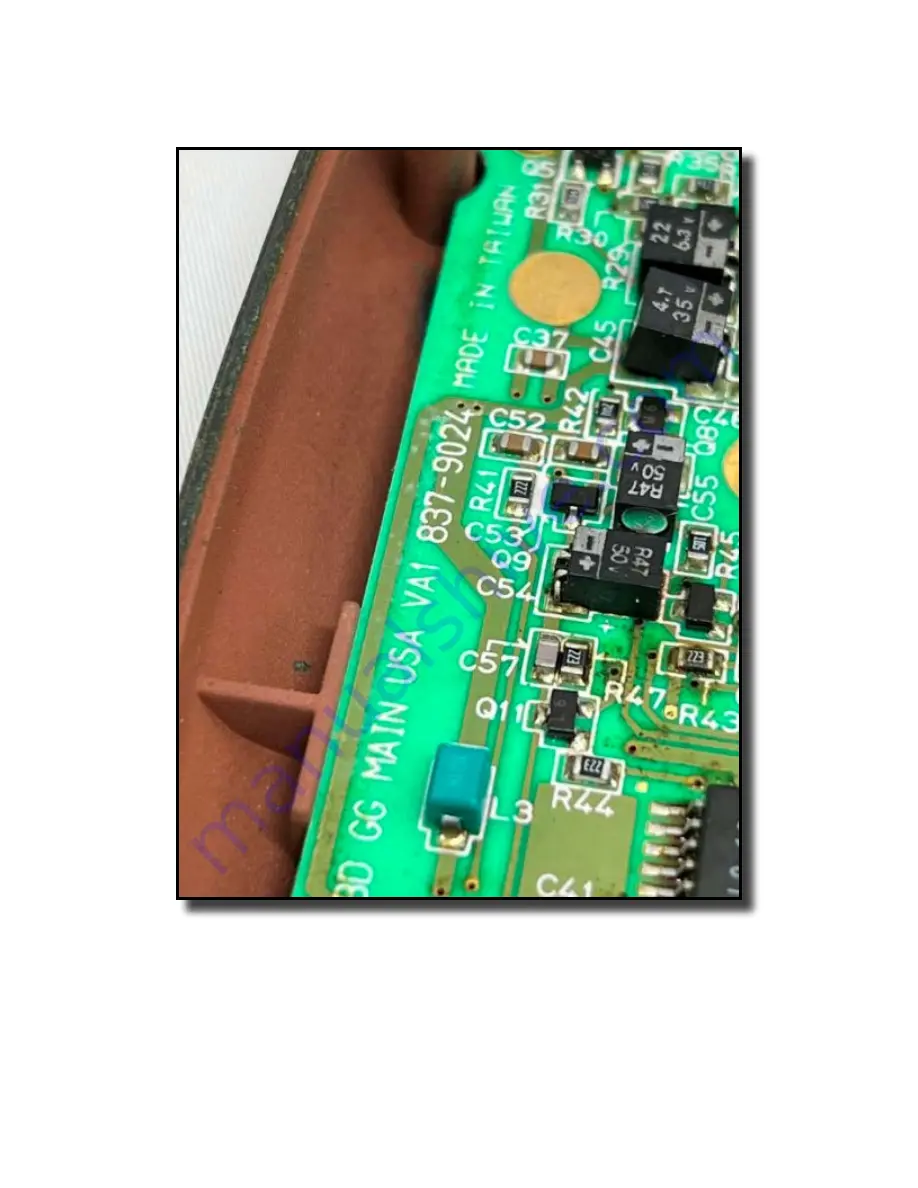

Ensure your Game Gear is compatible with this modification by finding a silkscreen that says “VA1”

when you open the case. If you see “VA1”, continue to step 3. All Dual ASIC models of Game Gear are

compatible with this mod.

NOTE

: If you are not using a Dual ASIC board or

DO NOT

see “VA1” and you see “VA4”, “VA5”, or do

not see “VA1” then your Game Gear is

NOT COMPATIBLE

with this version of the hardware. A further

hardware revision will include support for these later models.