© Galvin Engineering Pty Ltd

Version 1, 2 June 2022, Page

3

of

4

Product Installation Guidelines

Version 1, 2

nd

June 2022, Page

3

of 4

INSTALLATION

INSTALLATION COMPLIANCE: Galvin Engineering products must be installed in accordance with these

installation instructions and in accordance with AS/NZS 3500, the PCA and your local regulatory requirements.

Water and/or electrical supply conditions must also comply to the applicable national and/or state standards.

Failing to comply with these provisions shall void the product warranty and may affect the performance of the

product.

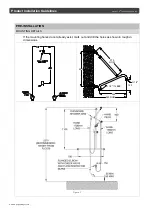

1. Top Flange

Mark the height of the top flange centre point by

measuring vertically 2275mm above the floor. Then

measure approximately 150mm horizontally to the

left or right (depending on the position of the

shower recess) of the centre of the existing supply

fitting. Drill 2 holes Ø8 x 50mm deep, 38mm

horizontally apart to suit the top flange.

2. Bottom Flange

Mark the position of the

bottom flange’s centre point

mm below the top flange’s centre

point. Then mark

the two holes for mounting the bottom flange in a similar

manner to the top flange.

Note:

The bottom flange is mounted in a vertical

orientation.

Important:

the functionality of this product relies on the

accuracy of the vertical alignment between the top and

bottom flanges.

3. Mount the shower arm

Attach both the wall flanges using the plastic star

plugs and self-tapping screws supplied (these

fasteners may not be appropriate for all wall

materials. If this is the case, other fastening

systems will have to be sourced by the installer).

4. Attach the hose

When fitting the inlet hose, lay the arm against the wall

in the

preferred ‘resting’ position, then tighten the hose.

The arm will tend to return to this position when not in

use.

38

DRILL 2 HOLES

Ø8x50 DEEP

2275mm ABOVE

THE FLOOR