ESTRO GT

4

FC66003937 - Rev 00

ALL COPYING, EVEN PARTIAL, OF THIS MANUAL IS STRICTLY FORBIDDEN

1.2

MAIN COMPONENTS

Cabinet

Composed of a painted steel sheet panel, side panels, air outlet grille

(swinging by 180°) and back suction grille built from ABS.

Structure

Built from galvanised steel sheet of extra thickness, heat and sound insu-

lated by means of Class 1 self-extinguishing panels. FU - FC - FF versions

are suitable for either vertical or horizontal installation thanks to the dual

condensate collection and drainage system.

Heat exchanger

High efficiency heat exchanger made with copper piping and aluminium

fins, provided with brass manifolds and vent valve. The water connections

are reversible at the time of installation. On request it is possible to mount

an additional heat exchanger for 4-pipe systems.

Air filter

Honey-comb polypropylene washable air filter, easily removable for main-

tenance operations. On FU version the air filters are fitted onto the air inlet

grille.

Electric fan with GreenTech BLDC motor

ESTRO GT uses the exclusive GreenTech technology of EBM-PAPST.

Permanent magnet BLDC motor with inverter integrated in the fan assembly,

protection rating IP44, insulation class F and ball bearings. Polypropylene

PP) volute. Centrifugal fan with forward-curving blades made of glassfilled

polyamide PA 6. Conformity with 2017 ERP Directive.

Backed by thirty years of experience in the manufacture of fan coil units

Galletti introduces the new ESTRO BLDC line.

Galletti fan coils can be equipped with a permanent magnet (brushless)

electric motor, controlled by an inverter, which enables continuous adjustment

in the number of fan revolutions.

The great advantage of brushless motors is the significant reduction in

power consumption, which in instant operations reaches up to a

1

/

3

of that

of conventional motors and at around 50% in integrated operations, with the

corresponding reduction in CO

2

emissions!

The DC Inverter technology allows to continuously adjust the air flow to the

actual needs of the environment by considerably reducing the fluctuations in

room temperature that are typical of step-by-step adjustments.

1.3

BLDC TECHNOLOGY

The direct consequence is also the reduction in the noise emission of the fan

coil, which is now proportional to the demands of the environment.

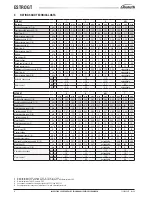

MAX speed

MED

speed

MIN

speed

winter set

winter (°C)

% opening

THE CONTROL

The operation of the unit with brushless motor is managed by the

MYCOMFORT LARGE control panel, using an analogue output (0-10V) which

is connected to the inverter.

The Galletti brushless fan coil thus represent the state of

the art due to the possibility of regulating the operation,

depending on the temperature of the air, its relative

humidity, the temperature of the water and based on the

programmable time slots.

By means of the digital outputs it is possible to switch on

and off external units or devices such as chiller, boiler,

pumps, water circulation pumps, etc.

Another analog output makes it possible to control the

modulating valves.

3 speed brushless motor temperature trend

3 speed brushless motor sound trend