9

Chapter

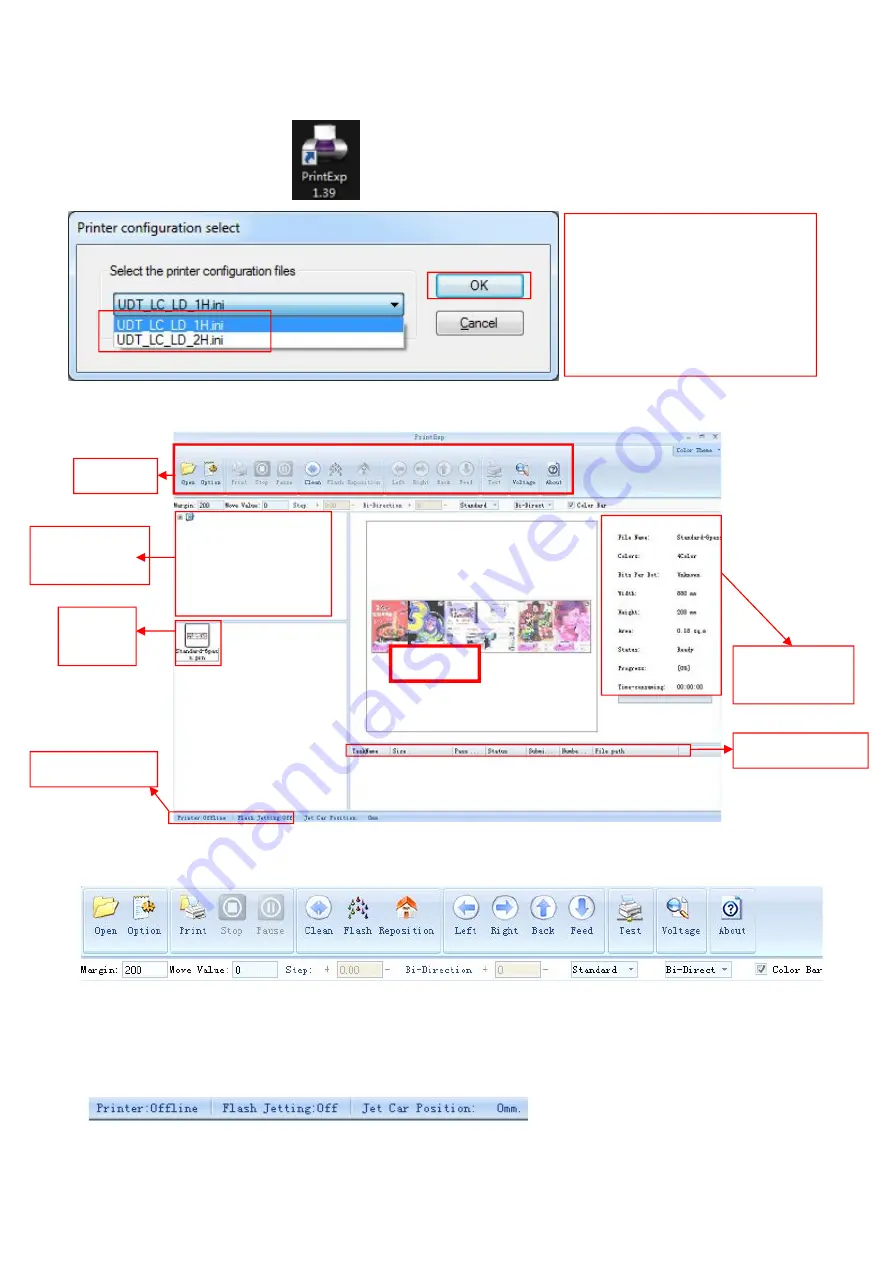

6. Software Interface

1) Introduction:

D

ouble click

to open the software.

2) Tools bar

We can speed up the implementation of commands by using tools bar which are commonly used function in the

software.

3)Status Bar

From the left to the right:

Printer status, Flash jetting function status, Carriage position

.

Preview

Image

information

Condition bar

Tools bar

Directory of

printing jobs

Jobs

to

Printing job list

Configuration definition

:

UDT_LC_LD_1H

:

LC or LD

model with 1 printhead.

UDT_LC_LD_2H

:

LC or LD

model with 2 printheads.