2

© 2016 Copyright All Rights Reserved

ESD2200 Electronic Speed Control Unit

10.14.16

PIB 1022

D

3

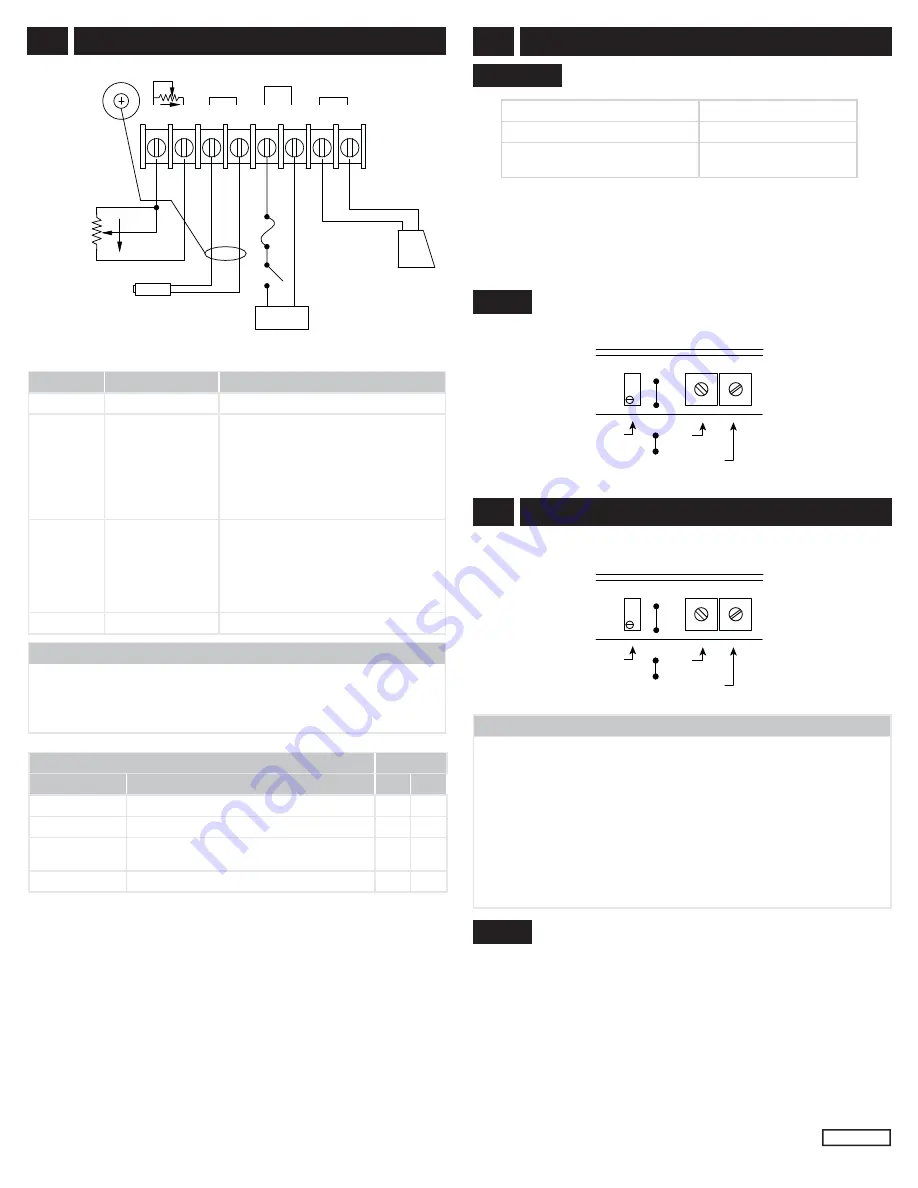

WIRING

A

B

C

D

E

F

G

H

ACTUATOR

PICK-UP

BATTERY

+

_

SPEED TRIM

OPTIONAL

SPEED TRIM

CONTROL

15A

FUSE

S1

BATTERY

ACTUATOR

MAGNETIC

SPEED PICK-UP

+

_

CW

4

5

STARTING THE ENGINE

ADJUSTING FOR STABILITY

The speed control unit governed speed setting is factory set at approximately

engine idle speed. (1000 Hz., Speed sensor signal or 600 RPM)

Crank the engine with DC power applied to the governor system. The actuator

will energize to the maximum fuel position until the engine starts. The governor

system should control the engine at a low idle speed. If the engine is unstable

after starting, refer to Section 5 ADJUSTING FOR STABILITY.

START FUEL ADJUSTMENT

1.

Rotate the GAIN adjustment clockwise until instability develops. Gradu-

ally move the adjustment counterclockwise until stability returns. Move

the adjustment one division further counterclockwise to insure stable

performance (270° pot).

2.

Rotate the STABILITY adjustment clockwise until instability develops.

Gradually move the adjustment counterclockwise until stability returns.

Move the adjustment one division further to insure stable performance

(270° pot).

3.

Gain and stability adjustments may require minor changes after engine

load is applied. Normally, adjustments made at no load achieve satis-

factory performance.

Gain

Middle Position

Stability

Middle Position

Speed Trim Control

(Infused)

Middle Position

IMPORTANT

Make sure the following adjustments are set before starting

the engine.

The governed speed set point is increased by clockwise rotation of

the SPEED adjustment control. Remote speed adjustment can be

obtained with an optional 5K Speed Trim Control.

NOTE

Once the engine is running at operating speed and at no load, the following

governor performance adjustments can be made to increase engine stability.

TERMINAL

DEFINITION

NOTES

A & B

Speed Trim

#18 AWG (1.3mm sq) or larger wire

C & D

Magnetic Speed

Pickup

(D is ground)

Wires must be twisted and/or shielded

for their entire length

Gap between speed sensor and gear

teeth should not be smaller than 0.02 in.

(.51mm)

Speed sensor voltage should be at least

1V AC RMS during crank

E & F

Battery Power (+/-)

#16 AWG (1.3mm sw) or larger wire

A 15 amp fuse must be installed in the

positive battery lead to protect against

reverse voltage

Battery positive (+) input is Terminal E

G & H

Actuator (+/-)

#16 AWG (1.3mm sw) or larger wire

RECOMMENDATIONS

1.

2.

Shielded cable should be used for all external connections to the ESD

control.

One end of each shield, including the speed sensor shield, should be

grounded to a single point on the ESD case.

If instability cannot be corrected or further performance improve-

ments are required, refer to Section 6 SYSTEM TROUBLE-

SHOOTING.

NOTE

SPEED

GAIN

STABILITY

E4

E5

SPEED

GAIN

STABILITY

E4

E5

Versions

Voltage

Part Number

Feature / Product Details

12V

24V

ESD2210

Standard Unit

X

X

ESD2241

Standard Unit with Idle

X

ESD2243

For Hoist FT/Operates with Foot Pedal,

5000 Hz Speed Range

X

ESD2244

Light Force (Low-Current Optimized PID)

X

X

25x

TORQE