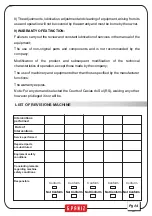

TECHNICAL SPECIFICATIONS

Designed as formation of pastas, breads ability to model up to 500g. Meet demand and

industrial kitchens, hotels, bakeries, bakeries similar with great efficiency, speed and quality.

It is manufactured in SAE 1020 carbon steel with epoxy paint. It has a closed cabinet, with

injected polypropylene bearings, shielded bearings, cylinders hard chrome finish. A

conveyor belt rollers, felts exchange system without disassembling the machine for

replacement.

Revenues for consultation, please visit: www.gpaniz.com.br

INSTALLATION

The following procedures must be made to improve the safety of users:

1) Install your equipment in a well ventilated area;

2) install the machine on a flat surface;

3) leave a space of at least 50 cm around the equipment;

4) check whether the mains voltage is the same team;

5) for proper operation, this appliance must be installed at room temperature 5

° C to 25 ° C.

6) Never use extensions or "T" for the connection of equipment;

7) Do not remove the ground pin cord;

8) using outlets 20A with 4.8mm pin according to NBR 6147.

The installation must be performed by a qualified and trained professional.

Call 0800-704-2366 and contact support if necessary.

TECHNICAL SPECIFICATIONS

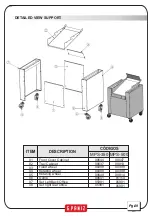

MODELADORA DE

PÃO

PRODUCT

MODEL

WEIGHT

LIQUID

CAPACITY

DE PASTA

DIMENSIONS

A X L X C

MPS-250

MPS-350

MPS-500

54 kg s/pedestal

58 kg s/pedestal

68 kg s/pedestal

105 kg s/pedestal

85 kg c/pedestal

Panes de até

500 g

Panes de até

500g

Panes de até

500g

400x400x730mm

1110x580x750mm

1110x740x750mm

NOTE:

The height shown in the above table is for MPS-350 and MPS-500 models Pedestal

mounted.

Pg.05