Operators and Technicians Manual

©

2006 – 2007 FutureLogic, Incorporated. All Rights Reserved.

MNL Page 4 of 29 12/06/2007

MNL-000030 REV.X07

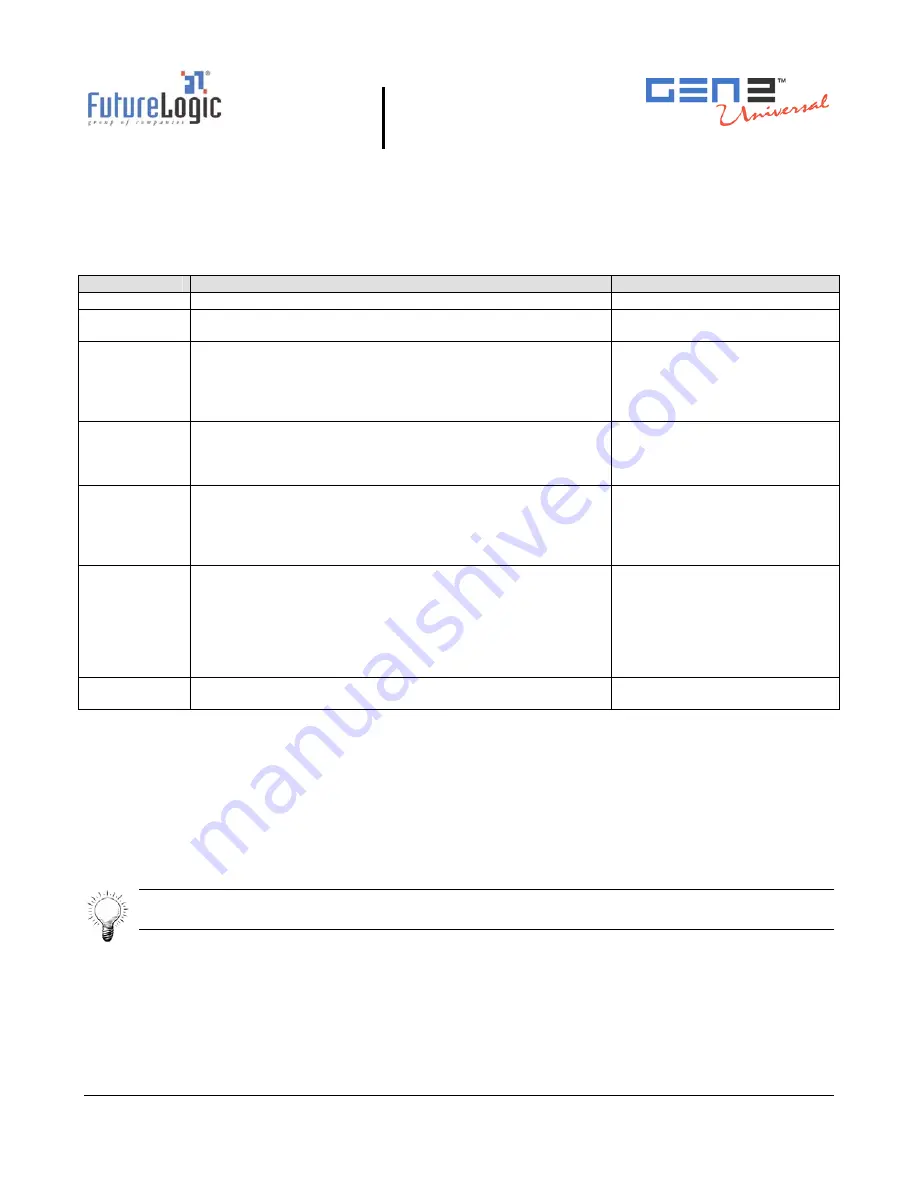

Printer Errors

Although there are a variety of error conditions that can occur, most printer errors are a result of the

printer running out of paper or the operator opening the lid. Table 2-4 lists possible errors and the

remedy for each condition.

Table 2-4

Errors and Error Descriptions

Error

Error Description

Remedy

Paper Out

Results when the printer does not detect paper present.

Load a new paper stack.

Head Up or

Open

Results from raising the head release lever or opening

the lid.

Lower the blue lever on the side

of the unit.

Temperature

Results when the printer is operating outside of its allowable

temperature range.

If the printer is operating in an environment where the

ambient temperature is roughly room temperature, this error

would most likely be the result of a hardware problem.

The printer will automatically

resume operation after the

detected head temperature falls

within range.

Voltage

Results if the printer detects a power supply voltage

(+24VDC to +25VDC) outside range.

This error could be the result of a poor cable connection.

The printer will automatically

resume operation after the

power supply is detected

within range.

Print Head

Results when the printer senses an internal error due to

connectivity or interfacing problem with the thermal print

head. This can be a result of a cable problem between the

main controller board and the printer engine.

The printer will remain in this

error state until the power is

cycled or the unit is reset.

If the problem persists, the

printer will require service.

Missing Black

Index Mark

Results if the paper type selected is indexed paper and while

feeding paper or printing a black mark is not seen within

approximately 10” of the paper.

This error alerts the user to the presence of the wrong kind

of paper in the printer or that the paper was inserted in

the wrong direction (so the black mark index is rotated

180 degrees).

Raise the head release lever

(presumably to change the

paper).

Paper Jam

Results when the printer detects an error in the paper path

for presenting the ticket to the customer.

Open the printer head and

inspect for a jammed ticket.

Loading Paper

Generally, the only printer service required is to load new paper stacks. Use the automatic

paper-loading feature to simplify this process to two steps: putting the paper stack into the Paper

Tray and feeding the paper to the Paper Loading Slot of the printer.

To load paper:

1.

Pull open the Printer Drawer until the Paper Tray is completely accessible.

2.

Place the paper stack in the printer as indicated by the band around the stack and the label on

the bottom of the Paper Tray.

Tip:

To prevent a new paper stack from sticking together, fan out the paper after you take

off the band.