16

Model name function

Assign a name to the model memory. By giving each model a name that is immediately recognizable, you can quickly select

the correct model, and minimize the chance of flying wrong model memory that could lead crash.

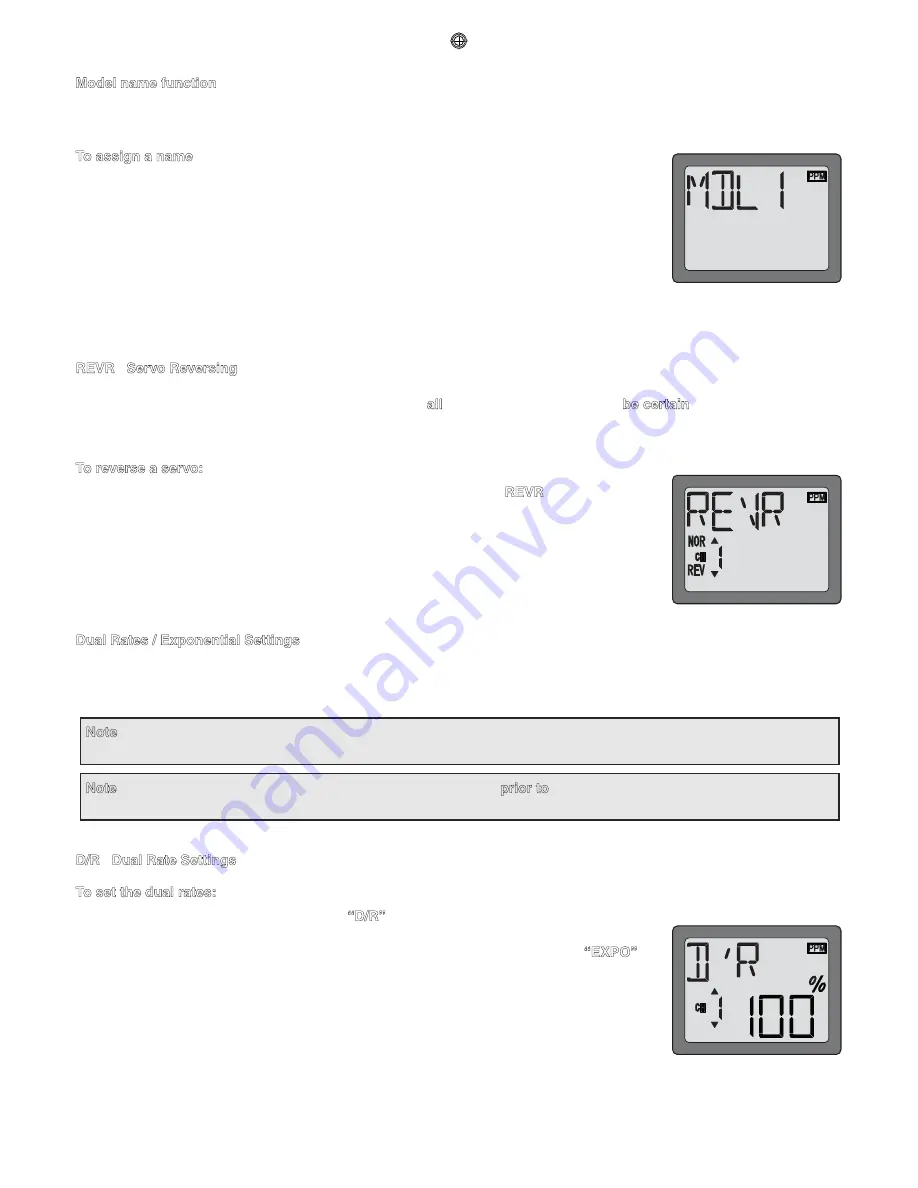

To assign a name

1. Access the Model Select function in the programming mode (by pressing the MODE and

SELECT keys simultaneously and holding them down for one second). To select the model

number you wish to change press the DATA INPUT lever and hold it down for 0.5 seconds

until the desired model number appears..

2. Push SELECT key five times after seeing on the screen the model memory where you want

to set the model name, then you will see the model name on the screen.

3. Choose a character for the first digit by using DATA INPUT lever. Then move to the next digit

by pressing the SELECT key and choose a character in the same way. Continue choosing

characters for the third and fourth digits. You can use up to four characters for the name.

REVR Servo Reversing

The servo reversing function is used to change the direction that a servo responds to a control input from the transmitter

(stick or switch). After using the reversing function, check

all

the controls on the model to

be certain

they are operating in the

correct direction and that you did not inadvertently reverse a servo other than the one intended. Reversing the wrong servo (and

not checking the response of the controls before each flight) may be the most common cause of a crash!

To reverse a servo:

1. Enter the programming mode and use the MODE key to access the

REVR

function.

2. Use the SELECT key to select the channel you wish to reverse.

3. Push the DATA INPUT lever downward for 0.5 seconds to reverse the servo (REV), or push

the lever upward for 0.5 seconds to make the servo operate normally (NOR). The arrow will

indicate the condition of the servo (normal or reversed).

4. Use the SELECT key to display other channels to be reversed.

Dual Rates / Exponential Settings

The aileron, elevator and rudder dual rates on the 6EXHP are simultaneously activated by the dual rate switch. The amount of

travel decrease for each control may be set between 0% and 100% of the values set for the end points (explained in End Point

Adjustment on page 17).

Note

: It is possible to set a dual rate value to zero, thus causing no response from that channel. If the dual rates are

inadvertently set to zero, a crash could result.

Note

: When performing initial model setup, the E.P.A.s should be set

prior to

setting the dual rates. When setting the E.P.A.s

for the first time on a new model, the dual rates should be set to 100%.

D/R Dual Rate Settings

To set the dual rates:

1. Enter the programming mode. Access the

“D/R”

screen with the MODE key.

2. Select the channel to be adjusted (1-aileron, 2-elevator, 4-rudder) by pressing the SELECT

key until the desired channel number the left side on the screen. Note: If a

“EXPO”

will

appear on the screen, you have pressed the SELECT key too many times and displayed

the values for the exponentials (explained later). Press the SELECT key to return to the dual

rate values.

3. Place the dual rate switch in the desired position for the value you wish to change. (Generally,

pilots prefer to have the switch in the “up” position for the high rate, and in the “down”

position for the low rate.)

4. Change the dual rate value using the DATA INPUT lever until the desired control throw is achieved. If you wish to change

the control throw when the switch is in the other position as well, flip the switch, then use the DATA INPUT lever to change