Product Specification

Page 17 of 18

1303090MS01

LA-309 Controlled Atmosphere Infrared Furnace

April 15, 2009

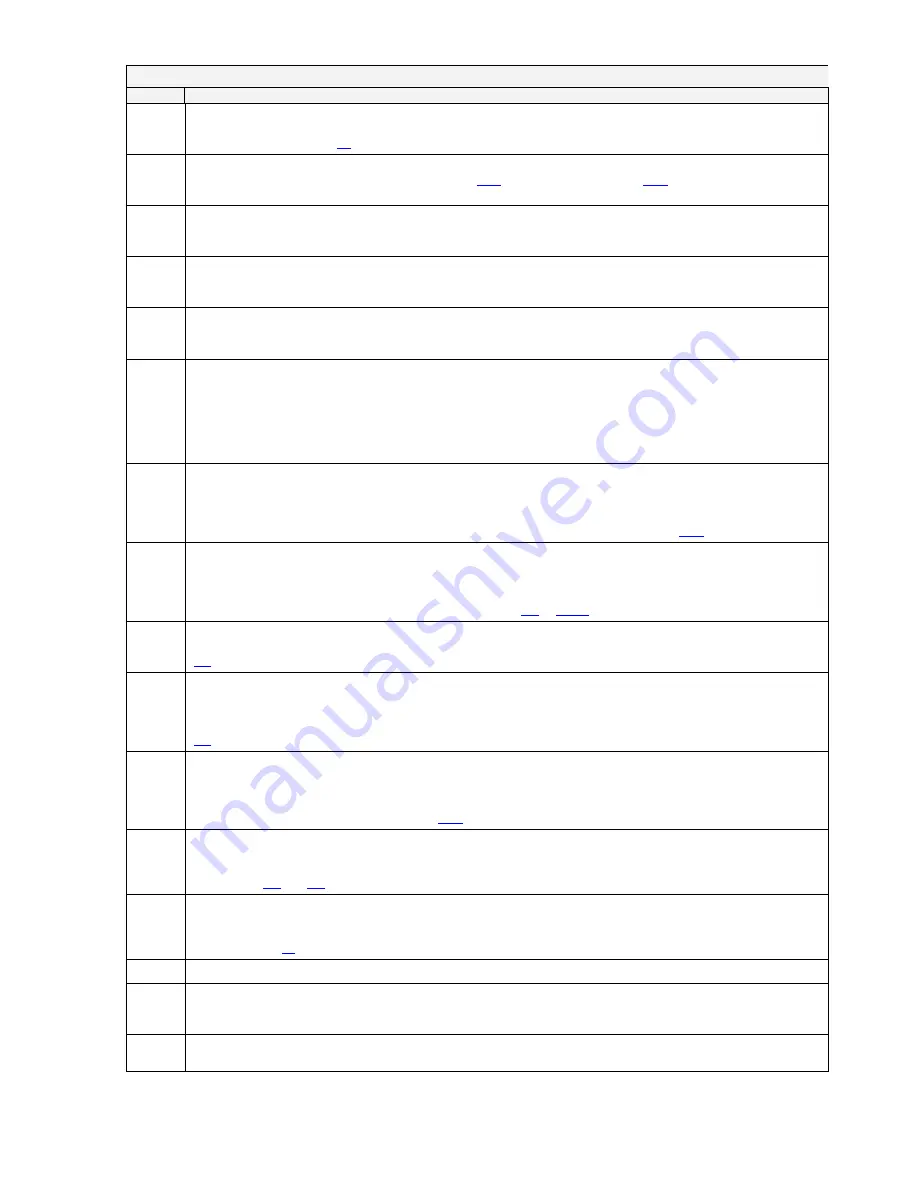

Table 17-1. Optional Equipment

KEY

DESCRIPTION

HSK Handshake

Signaling.

NO and NC signals to upstream and downstream equipment or to the production line

controller about the furnace status when the furnace is part of an automatic production line.

Requires the Process

Ready/Alarm Light Tower (

) option. Option available on all furnaces.

HT High

Temperature

Operation.

High temperature construction for furnace operation above 500°C up to 1000°C.

Includes upgraded insulation and materials, changes

316 stainless steel belt to

Nichrome material, and

adds cabinet temperature thermocouple plus alert/alarm on cabinet temperature.

Option available on most furnaces.

IPS

Inlet Pressure Switch.

Pressure switch upstream of the gas distribution system that signals the operator and the

furnace control system in the event of pressure loss in the process gas supply line. Furnace PROCESS START

mode will be inhibited automatically until pressure is restored to normal.

Option available on most furnaces.

IR-E

Interface Roller, Entrance.

Small diameter belt rollers at the entrance of the furnace that permit close transfer of

parts from upstream conveyor equipment. The rollers are less than 3 inches (76.2 mm) in diameter. Adds 6.4 cm (2.5

inch) to the length of the furnace.

Option available on most furnaces.

IR-X

Interface Roller, Exit:

Small diameter belt rollers at the exit of the furnace that permit close transfer of parts to

downstream conveyor equipment. The rollers will be less than 3 inches (76.2 mm) in diameter. Adds 6.4 cm (2.5

inch) to the length of the furnace.

Option available on most furnaces.

LT

Process Ready/Alarm Light Tower:

Provides a three stage alarm status light tower. The status system activates a

three element alarm light, located above the upper frame, as follows:

o

Red Indicator: Alarm Condition, audible alarm

o

Yellow Indicator: Process Not Ready, no alarm

o

Green Indicator: Process Ready, no alarm

Option available on most furnaces.

MA Moisture

Analyzer:

Provides a moisture monitoring system for the process atmosphere in a furnace with a hermetic

sealed chamber. A gas sample is withdrawn continuously from a sample port in the furnace chamber through the

analyzer. A switched pump and vacuum break are provided to withdraw the sample. The analyzer is provided with

an inline 1µm filter for removal of particulates from the sample flow. ProControl™ OIT displays dew point in ºC or

moisture as PPM, and alert/alarm conditions.

Option available on most furnaces. Requires

option.

N2-S Nitrogen

Auto

Gas

Shutoff:

Automatically opens the nitrogen supply inlet valve when the control system is started,

prior to furnace entering WARM UP mode, and automatically shuts off that valve at furnace shutdown after COOL

DOWN mode is complete. Can help minimize waste of process gas and relieves the operator having to return to the

machine to shut off the process gas when the furnace has cooled down. Includes timed delay to assure clearing of all

process gas and emissions from furnace chamber.

Requires

, option available on most furnaces.

NGFS Nitrogen/Forming

Gas

Selector.

Allows ability to select between nitrogen (N

2

) or a nitrogen hydrogen (N

2

/H

2

) mix

(forming gas) process atmosphere in heating chamber of the furnace, depending on process requirements.

Requires

. Option available on most furnaces.

NO Nitrogen

Operation.

Allows for efficient use of nitrogen (N

2

) in the furnace, minimizing consumption where an N

2

process atmosphere is required. N

2

is supplied only to oxygen-controlled areas (entrance baffle, heating chamber,

and transition tunnel), while CDA is supplied to eductors and cooling. Controlled atmosphere processes should be

reviewed to assure that the product is below its oxidation temperature before reaching cooling section.

Order with

, standard on some furnaces, option available on most furnaces.

OA Oxygen

Analyzer:

Provides an oxygen monitoring system for the process atmosphere in a furnace with a hermetic

sealed chamber. A gas sample is withdrawn continuously from a sample port in the furnace chamber through the

analyzer. A switched pump and vacuum break are provided to withdraw the sample. The analyzer is provided with

an inline 1 µm filter for removal of particulates from the sample flow. ProControl™ OIT displays oxygen concentration

in PPM, and alert/alarm conditions.

-On-line Gas Sampling. System, option available on most furnaces.

OSS

On-line Gas Sampling System:

The sampling system provides 4 selectable inputs: 3 sample ports in the furnace

and 1 port with a 13.7 kPa (2 psi) regulator in-line for source gas monitoring or sensor purging to improve sensor

response during startup of sampling. System may be turned on/off and any of the 4 inputs selected via the furnace OI.

Required for

options, option available on most furnaces

OT

Over-temperature Monitor & Shutdown Alarm.

Provides completely independent temperature measurement in

each zone with audible alarm and automatic furnace shutdown for temperatures out of range. Includes second

thermocouple for each zone directly connected to separate zone scanner and monitor with display. Alarm integrated

with the furnace

Option available on most furnaces.

PCMS

Computer Monitor, Special.

Option available on most furnaces.

PH1

Parts Height, 1 inch.

Reduces clearance at all baffle and cooling section throats, and zone dividers ) to 25 mm (1

inch) from the standard 51 mm (2 inch). Allows for larger zone-to-zone temperature differences for small parts.

Option available on most furnaces.

PH4

Parts Height, 4 inch.

Raises clearance at all baffle and cooling section throats, and zone dividers to 102 mm (4 inch)

from the standard 51 mm (2 inch).

Option available on most furnaces.

Summary of Contents for LA-309

Page 5: ...10 004 676 110000 v WARRANTY Warranty goes here ...

Page 6: ...vi LA 309 Owner s Manual ...

Page 12: ...Contents xii LA 309 Owner s Manual ...

Page 20: ...Section 1 1 8 LA 309 Owner s Manual ...

Page 68: ...Section 3 3 28 LA 309 Owner s Manual ...

Page 70: ...Section 4 4 2 LA 309 Owner s Manual ...

Page 72: ...Section 4 4 4 LA 309 Owner s Manual ...

Page 98: ...Section 5 5 2 LA 309 Owner s Manual ...

Page 100: ...Section 5 5 4 LA 309 Owner s Manual ...

Page 106: ...Section 5 5 10 LA 309 Owner s Manual ...

Page 108: ...Section 5 5 12 LA 309 Owner s Manual ...

Page 110: ...Section 5 5 14 LA 309 Owner s Manual ...

Page 112: ...Section 6 6 2 LA 309 Owner s Manual ...

Page 114: ......

Page 115: ......

Page 126: ...Section 7 1 Fiberfrax Cements MSDS 042006 Owner s Manual ...

Page 139: ...MSDS 2 Fiberfrax Duraboard MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 140: ...Section 7 2 Fiberfrax Duraboard MSDS 042006 Owner s Manual ...

Page 153: ...MSDS 3 Fiberfrax Fibers MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 154: ...Section 7 3 Fiberfrax Fibers MSDS 042006 Owner s Manual ...

Page 167: ...MSDS 4 Fiberfrax Papers MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 168: ...Section 7 4 Fiberfrax Papers MSDS 042006 Owner s Manual ...

Page 181: ...MSDS 5 Magnaform MSDS 050406 MATERIAL SAFETY DATA SHEETS ...

Page 182: ...Section 7 5 Magnaform MSDS 050406 Owner s Manual ...

Page 183: ......

Page 184: ......

Page 185: ...Section 7 6 RTU Silicone Red Hi Temp 042006 Owner s Manual ...

Page 186: ...MSDS 6 RTU Silicone Red Hi Temp 042006 MATERIAL SAFETY DATA SHEETS ...

Page 189: ...Section 7 7 Kaowool Insulation MSDS 050406 Owner s Manual ...

Page 190: ...MSDS 7 Kaowool Insulation MSDS 050406 MATERIAL SAFETY DATA SHEETS ...

Page 201: ...Material Safety Data Sheets 7 15 Notes ...

Page 202: ...Section 7 7 16 Owner s Manual ...

Page 204: ...Section 8 Owner s Manual ...

Page 206: ...Section 8 Owner s Manual ...

Page 212: ...iv Operation and Troubleshooting ...

Page 214: ...vi Operation and Troubleshooting ...

Page 224: ...Page 10 Operation and Troubleshooting ...

Page 231: ...9 1 Section 9 APPENDIX B 9 1 EC913 CALIBRATION REPORT 9 2 SERIES EC900 OXYGEN ANALYZERS ...

Page 232: ...Section 8 Owner s Manual ...

Page 233: ......

Page 234: ...Section 8 Owner s Manual ...

Page 279: ...Section 8 Owner s Manual ...

Page 281: ...MSDS MATERIAL SAFETY DATA SHEETS ...

Page 282: ...16 Notes ...