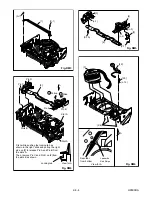

2-3-2

H9500MA

Adjust the X Value for maximum envelope.

(pg. 2-3-3) (Use Alignment Tape.)

Check to see that the tape is not creasing

and that there is no slack on the supply

and take-up side Guide Rollers.

(Use a blank tape.)

Adjust the height of the Guide Rollers

(Supply side and take-up side).

(Use a blank tape.) (pg. 2-3-3)

Loading (Use a blank tape.)

Adjust the envelope. (pg. 2-3-4)

Check the envelope.

Adjust the Audio Section.

(Azimuth Alignment) (pg. 2-3-4)

Check the audio output.

Check the following:

1. X Value (pg. 2-3-3)

2. Envelope (pg. 2-3-4)

Adjust the X value and envelope.

Not good

Do the final tape-traveling test to see that

the tape runs normally in play mode with-

out creasing or slacking.

Completion

Not good

OK

OK

OK

Not good

Not good

OK

Flowchart of Alignment for tape traveling

1-A

1-A

1-B

1-C

1-C

1-D

1-D

1-B, 1-C

1-B, 1-C

1-A

1.Tape Interchangeability Alignment

Note:

To do these alignment procedures, make sure that the

Tracking Control Circuit is set to the center position

every time a tape is loaded or unloaded. (Refer to

page 2-3-4, procedure 1-C, step 2.)

Equipment required:

Dual Trace Oscilloscope

VHS Alignment Tape (FL6NS8)

Guide Roller Adj. Screwdriver

X-Value Adj. Screwdriver

Note: Before starting this Mechanical Alignment, do all

Electrical Adjustment procedures.

Summary of Contents for DPVR-4604

Page 29: ...Main 1 10 Schematic Diagram VCR Section 1 10 3 1 10 4 H95B0SCM1...

Page 31: ...1 10 7 1 10 8 H95B0SCM3 Main 3 10 Schematic Diagram VCR Section...

Page 32: ...Main 4 10 Schematic Diagram VCR Section 1 10 9 1 10 10 H95B0SCM4...

Page 33: ...Main 5 10 Schematic Diagram VCR Section 1 10 11 1 10 12 H95B0SCM5...

Page 34: ...Main 6 10 Schematic Diagram VCR Section 1 10 13 1 10 14 H95B0SCM6...

Page 35: ...Main 7 10 Schematic Diagram VCR Section 1 10 15 1 10 16 H95B0SCM7...

Page 36: ...Main 8 10 DVD Open Close Schematic Diagram VCR Section 1 10 17 1 10 18 H95B0SCM8...

Page 37: ...1 10 19 1 10 20 Main 9 10 Schematic Diagram VCR Section H95B0SCM9...

Page 38: ...Main 10 10 Schematic Diagram VCR Section 1 10 21 1 10 22 H95B0SCM10...

Page 40: ...1 10 25 1 10 26 Jack Schematic Diagram VCR Section H95B0SCJ...

Page 41: ...1 10 27 1 10 28 Function Schematic Diagram VCR Section H95B0SCF...

Page 42: ...1 10 29 1 10 30 AFV Schematic Diagram VCR Section H95B0SCAFV...

Page 44: ...1 10 33 Main CBA Bottom View BH9510F01014A 1 10 34...

Page 48: ...DVD Main 1 3 Schematic Diagram DVD Section H95B0SCD1 1 10 41 1 10 42...

Page 49: ...1 10 43 1 10 44 DVD Main 2 3 Schematic Diagram DVD Section H95B0SCD2...

Page 51: ...DVD Main 3 3 Schematic Diagram DVD Section 1 10 47 H95B0SCD3 1 10 48...

Page 98: ...DPVR 4604 H95B0ED...