9

CHOOSING AN OPERATION MODE

The Full Boar FBT-0500 has 4 different operating modes: drilling, hammer drilling, chiselling

with fixation and chiselling without fixation. Follow the below instructions to select your

desired mode of operation.

Hammer Drilling

Rotate the side mode selector to the

drill icon, and rotate the rear mode

selector to the hammer icon. This

setting is recommended for use when

drilling holes in concrete and other

masonry products. The hammer

action will be in operation while

simultaneously the drill bit rotates.

Chiselling (free rotation)

Rotate the side mode selector to the

free rotation chiselling mode & rotate the

rear mode selector to the hammer icon.

This setting is helpful when you want to

have the chisel in a particular position.

The bit will stop rotating once contact is

made with the material, or you can rotate

the bit by hand. Once you have found

the ideal position, you can change to

chiselling (locked) for continual use.

Drilling

Rotate the side mode selector to the

drill icon, and rotate the rear mode

selector to the no hammer icon.

This setting is recommended for use

when you desire the accessory to

rotate without hammer action. Ideal

for drilling into timber or steel when

correct accessories for such materials

are used.

Side Mode

Selector

Rear Mode

Selector

Chiselling (locked)

Rotate the side mode selector to the

chisel icon, and rotate the rear mode

selector to the hammer icon. This

setting is recommended for use when

you desire a hammer action without

the accessory rotating which is ideal

for “chiseling or chipping” away at

masonry products, pick or chisel

accessory bits should be used.

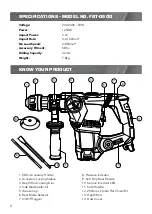

Summary of Contents for FBT-0500

Page 15: ...15...