En-4

Table 1

Flare nut tightening torque

Flare nut

Diameter (mm)

x Torque (N • m

)

6.35 mm dia.

17 x

16 ~ 18

12.7 mm dia.

26 x 49 ~ 61

Table 2

Pipe outside diameter

Pipe outside

diameter

A (mm)

Flare tool for

R410A, clutch type

Conventional (R22) Flaring tool

Clutch type

Wing nut type

ø 6.35 mm (1/4")

0 to 0.5

1.0 to 1.5

1.5 to 2.0

ø 12.7 mm (1/2")

0 to 0.5

1.0 to 1.5

1.5 to 2.0

CAUTION

Fasten a

fl

are nut with a torque wrench as instructed in this manual. If fastened too

tight, the

fl

are nut may be broken after a long period of time and cause a leakage of

refrigerant.

During installation, make sure that the refrigerant pipe is attached

fi

rmly before you run

the compressor. Do not operate the compressor under the condition of refrigerant piping

not attached properly with 2-way or 3-way valve open. This may cause abnormal pres-

sure in the refrigeration cycle that leads to breakage and even injury.

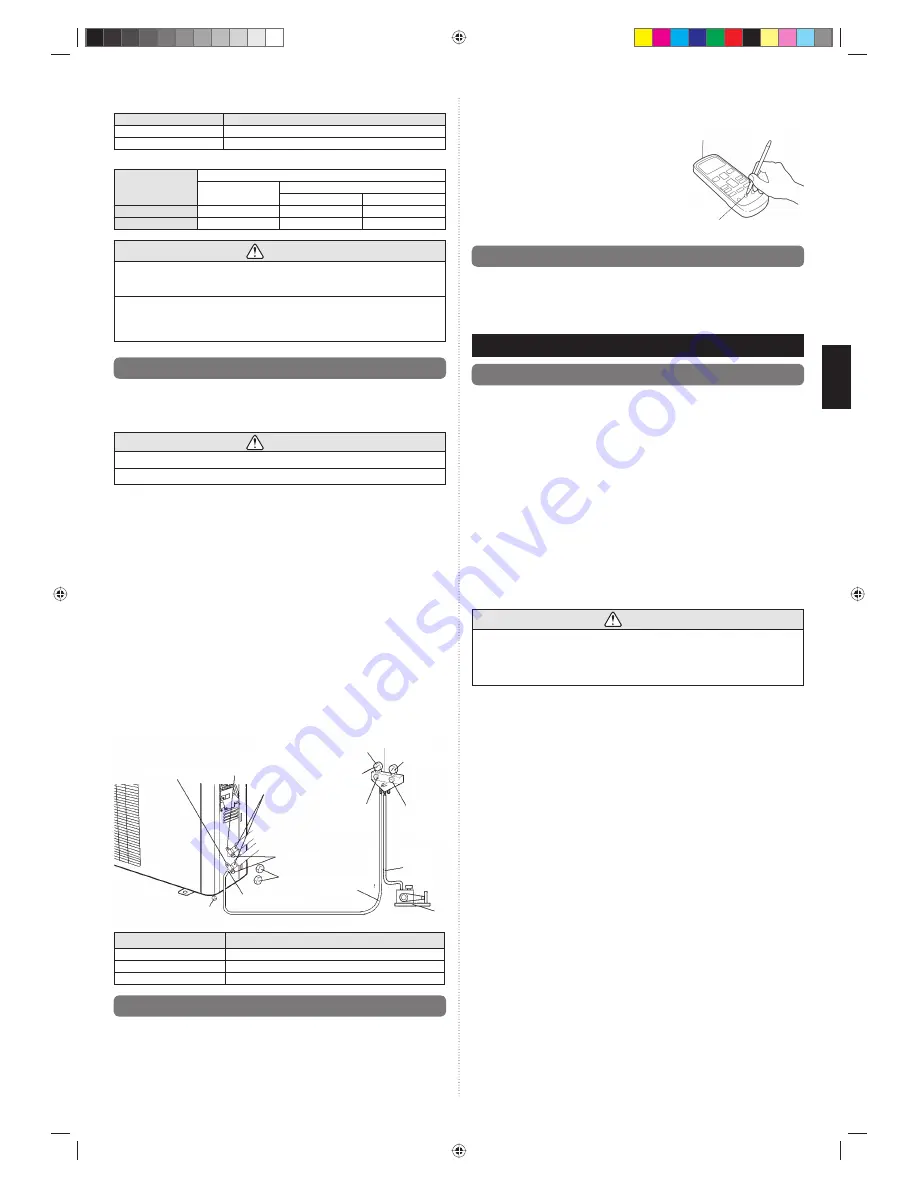

5.6. Air purge

Always use a vacuum pump to purge the air.

Refrigerant for purging the air is not charged in the outdoor unit at the factory.

Close the high pressure side valve of the gauge manifold fully and do not operate it during

the following work.

CAUTION

Refrigerant must not be discharged into atmosphere.

After connecting the piping , check the joints for gas leakage with gas leak detector.

(1) Check if the piping connections are secure.

(2) Check that the stems of 2-way valve and 3-way valve are closed fully.

(3) Connect the gauge manifold charge hose to the charging port of the 3-way valve (side

with the projection for pushing in the valve core).

(4) Open the low pressure side valve of the gauge manifold fully.

(5) Operate the vacuum pump and start pump down.

(6) Slowly loosen the

fl

are nut of the 3-way valve and check if air enters, then retighten

the

fl

are nut.

(When the

fl

are nut is loosened the operating sound of the vacuum pump changes

and the reading of the compound pressure gauge goes from minus to zero.)

(7) Pump down the system for at least 15 minutes, then check if the compound pressure

gauge reads -0.1 MPa (-76 cmHg, -1 bar).

(8) At the end of pump down, close the low pressure side gauge of the gauge manifold

fully and stop the vacuum pump.

(9) Slowly loosen the valve stem of the 3-way valve. When the compound pressure

gauge reading reaches 0.1-0.2 MPa, retighten the valve stem and disconnect the

charge hose from the 3-way valve charging port.

(If the stem of the 3-way valve is opened fully before the charge hose is disconnect-

ed, it may be dif

fi

cult to disconnect the charge hose.)

(10) Fully open the valve stems of the 2-way valve and 3-way valve using a hexagon

wrench. (After the valve stem begins to turn, turn it with a torque of less than

2.9 N • m (30 kgf • cm) until it stops turning.)

(11) Firmly tighten the 2-way valve and 3-way valve blank cap and the charging port cap.

3-way valve

2

-way valve

Charging

port cap

Vacuum pump

Charge

hose

Charge hose

Charging port

Blank cap

Valve stem

Flare nut

Compound pressure gauge

Gauge manifold

Pressure gauge

High

pressure

side valve

(closed)

Low

pressure

side

valve

-0.1 MPa

(-76 cmHg

-1 bar)

Tightening torque

Blank cap (2-way valve)

20.0 to 25.0 N • m (200 to 250 kgf • cm)

Blank cap (3-way valve)

28.0 to 32.0 N • m (280 to 320 kgf • cm)

Charging port cap

12.5 to 16.0 N • m (125 to 160 kgf • cm)

5.7. TEST RUN

•

Perform test operation and check items below.

•

For the test operation method, refer to the operating manual.

•

The outdoor unit, may not operate, depending on the room temperature. In this case,

press the test run button on the remote controller while the air conditioner is running,

(Point the transmitter section of the remote controller toward the air conditioner and

press the test run button with the tip of a ball-point pen, etc.)

•

To end test operation, press the remote controller START/STOP button.

(When the air conditioner is run by pressing the test run button, the OPERATION indica-

tor lamp and TIMER indicator lamp will simultaneously

fl

ash slowly.)

OUTDOOR UNIT

(1) Is there any abnormal noise and vibration during

operation?

(2) Will noise, wind, or drain water from the unit

disturb the neighbors?

(3) Is there any gas leakage?

5.8. CUSTOMER GUIDANCE

Explain the followings to the customer in accordance with the operating manual:

(1) Starting and stopping method, operation switching, temperature adjustment, timer,

air

fl

ow switching, and other remote controller operations.

(2) Air

fi

lter removal and cleaning, and how to use the air

fl

ow direction louvers.

(3) Give the operating and installation manuals to the customer.

6. PUMP DOWN

6.1. Pump down

PUMP DOWN OPERATION (FORCED COOLING OPERATION)

To avoid discharging refrigerant into the atmosphere at the time of relocation or disposal,

recover refrigerant by doing the cooling operation or forced cooling operation according

to the following procedure. (When the cooling operation cannot start in winter, and so on,

start the forced cooling operation.).

(1) Do the air purging of the charge hose by connecting the charging hose of gauge mani-

fold to the charging port of 3-way valve and opening the low-pressure valve slightly.

(2) Close the valve stem of 2-way valve completely.

(3) Start the cooling operation or following forced cooling operation. Keep on pressing the

MANUAL AUTO button of the indoor unit for more than 10 seconds. The operation in-

dicator lamp and timer indicator lamp will begin to flash simultaneously during test run.

(The forced cooling operation cannot start if the MANUAL AUTO button is not kept on

pressing for more than 10 seconds.)

(4) Close the valve stem of 3-way valve when the reading on the compound pressure

gage becomes 0.05~0 Mpa(0.5~0 kg/cm

2

).

(5) Stop the operation.

• Press the START/STOP button of the remote control unit to stop the operation.

• Press the MANUAL AUTO button when stopping the operation from indoor unit side. (It

is not necessary to press on keeping for more than 10 seconds.)

CAUTION

During the pump-down operation, make sure that the compressor is turned off before

you remove the refrigerant piping.

Do not remove the connection pipe while the compressor is in operation with 2-way or

3-way valve open. This may cause abnormal pressure in the refrigeration cycle that

leads to breakage and even injury.

Transmitter section

Test

run

button

9377863119_IM.indb 4

9377863119_IM.indb 4

1/20/2011 6:10:41 PM

1/20/2011 6:10:41 PM