En-7

6. ELECTRICAL WIRING

Cable

Cable size (mm

2

)

Type

Remarks

Connection cable

1.5 (MIN.)

Type 60245 IEC57

earth (ground),

1

φ

230V

Max. Cable Length: Limit voltage drop to less than 2%. Increase cable gauge if voltage drop is

2% or more.

•

Install all electrical works in accordance to standard.

•

Install the disconnect device with a contact gap of at least 3mm in all poles nearby

the units. (Both indoor unit and outdoor unit)

•

Wiring size must comply with the applicable country or region's regulations.

WARNING

• Electrical work must be performed in accordance with this Manual by a person

certi

fi

ed under the national or regional regulations. Be sure to use a dedicated circuit

for the unit.

An

insuf

fi

cient power supply circuit or improperly performed electrical work can cause

serious accidents such as electric shock or

fi

re.

• Before starting work, check that power is not being supplied to the indoor unit and

outdoor unit.

• For wiring, use the prescribed type of cables, connect them securely, making sure

that there are no external forces of the cables applied to the terminal connections.

Improperly connected or secured cables can cause serious accidents such as

overheating the terminals, electric shock, or

fi

re.

• Securely install the electrical box cover on the unit.

An improperly installed electrical box cover can cause serious accidents such as

electric shock or

fi

re through exposure to dust or water.

• Install sleeves into any holes made in the walls for wiring. Otherwise, a short circuit

could result.

• Use the included connection cables and power cables or ones specified by the

manufacturer. Improper connections, insufficient insulation, or exceeding the

allowable current can cause electric shock or

fi

re.

• Do not modify the power cables, use extension cables, or use any branches in the

wiring. Improper connections, insufficient insulation, or exceeding the allowable

current can cause electric shock or

fi

re.

• Match the terminal block numbers and connection cable colors with those of the

outdoor unit. Erroneous wiring may cause burning of the electric parts.

• Securely connect the connection cables to the terminal board. In addition, secure the

cables with wiring holders. Improper connections, either in the wiring or at the ends

of the wiring, can cause a malfunction, electric shock, or

fi

re.

• Always fasten the outside covering of the connection cable with the cable clamp. (If

the insulator is chafed, electric leakage may occur.)

• Install a earth leakage breaker. In addition, install the earth leakage breaker so that

the entire AC main power supply is cut off at the same time. Otherwise, electric shock

or

fi

re could result.

• Always connect the earth (ground) cable.

Improper earthing (grounding) work can cause electric shocks.

• Install the remote controller cables so as not to be direct touched with your hand.

• Perform wiring work in accordance with standards so that the air conditioner can be

operated safely and positively.

• Connect the connection cable

fi

rmly to the terminal board. Imperfect installation may

cause a

fi

re.

CAUTION

• Earth (Ground) the unit.

Do not connect the earth (ground) cable to a gas pipe, water pipe, lightning rod, or a

telephone earth (ground) cable.

Improper earthing (grounding) may cause electric shock.

• Do not connect power supply cables to the transmission or remote controller

terminals, as this will damage the product.

• Never bundle the power supply cable and transmission cable, remote controller cable

together.

Separate these cable by 50 mm or more.

Bundling these cables together will cause miss operation or breakdown.

• When handling PCB, static electricity charged in the body may cause malfunction of

the PCB. Follow the cautions below:

• Establish a ground for the indoor and outdoor units and peripheral devices.

• Cut power (breaker) off.

• Touch metal part of the indoor and outdoor units for more than 10 seconds to

discharge static electricity charged in the body.

• Do not touch terminals of parts and patterns implemented on PCB.

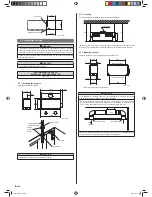

(1) Use ring terminals with insulating sleeves as shown in the

fi

gure below to connect to

the terminal block.

(2) Securely clamp the ring terminals to the cables using an appropriate tool so that the

cables do not come loose.

(3) Use the speci

fi

ed cables, connect them securely, and fasten them so that there is no

stress placed on the terminals.

(4) Use an appropriate screwdriver to tighten the terminal screws.

Do not use a screwdriver that is too small, otherwise, the screw heads may be

damaged and prevent the screws from being properly tightened.

(5) Do not tighten the terminal screws too much, otherwise, the screws may break.

(6) See the table for the terminal screw tightening torques.

(7) Please do not

fi

x 2 power supply cables with 1 screw.

Strip 10 mm

Sleeve

Screw with

special washer

Screw with

special washer

Ring terminal

Cable

Cable

Terminal block

Ring terminal

Ring

terminal

WARNING

• Use ring terminals and tighten the terminal screws to the speci

fi

ed torques, otherwise,

abnormal overheating may be produced and possibly cause heavy damage inside

the unit.

Tightening torque [N·m (kgf·cm)]

M4 screw

1.2 to 1.8

(12 to 18)

M5 screw

2.0 to 3.0

(20 to 30)

9379123037-02.indb 7

9379123037-02.indb 7

7/4/12 3:47 PM

7/4/12 3:47 PM